Equipment

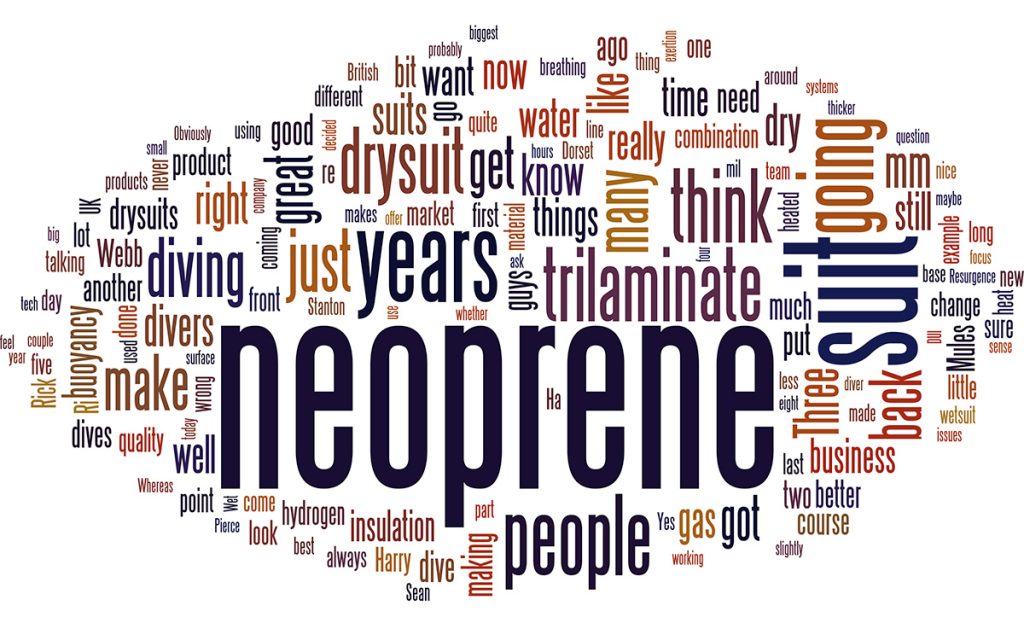

Come Out of the Bloody Cold: The Case for Neoprene with O’Three founder Sean Webb

By Michael Menduno. Images courtesy of Sean Webb unless noted.

There is arguably some confusion in the tech diving community over the advantages and disadvantages of neoprene suits versus the perceived virtues of trilaminates. Accordingly, InDEPTH chief Michael Menduno conducts a deep dive into the case for neoprene with head neo-advocate Sean Webb, founder and president of veteran British suit maker O3. The pair even take a short excursion into hydrogen diving with an O3 ambassador—the Wet Mules’ Dirty Harry. Are you feeling lucky today Punk?

It’s not an exaggeration to say that Sean Webb has been working to keep divers warm for nearly 40 years. The 56-year-old, water baby turned diving business veteran made his first scuba dive at age nine when his father helped him strap on a 10-liter aqualung and attached a rope tether to restrict his depth to two meters/six feet. Webb was hooked. Six years, two dive clubs and numerous dives later, he earned his ocean diver certification at the BSAC’s Weymouth Dorset Club.

The next year, Webb followed his dreams and joined Ron and Joy Parry’s family dive business, SubAquatics, which they had founded in the 50s, in order to make neoprene wetsuits and drysuits. The teenage waterman never looked back. In 1989, when the family business dissolved, Webb decided to stick with what he knew and formed O’Three. He was later joined by one of the Parry sons. The name is derived from the chemical symbol of ozone, O3, which was one of the big environmental issues of that time.

Webb is surrounded by water on the limestone-tied island of Portland on the UK’s Dorset coast—the Jurassic Coast as it is known—which has been designated a United Nations World Heritage Site. Here, the boutique British drysuit maker quietly built a following and a reputation for making dry, warm, high quality neoprene drysuits that has continued on to this day, some 33 years later—no small feat for a diving business! In recent years, O’Three added wetsuits, and most recently a trilaminate suit in response to market pressure.

O’Three’s ambassadors and friends include Australia’s Wet Mules, who are conducting some extraordinary exploration, and knighted British diver Sir Rick Stanton of Thai cave rescue fame. Then there’s dive training veteran and RAID vice president Steve Lewis, the training officer for the Somerset Section of the British Cave Diving Group Michael Thomas, and YouTube influencer “Adventures With Purpose” principal Jared Leisek, to name a few.

Full disclosure: I am an ambassador as well, and own an O’Three Ri-2 100 neoprene drysuit. I am also a Fourth Element ambassador and dive an Argonaut 2.0 trilaminate suit. You could say I’m a bit of a Anglophile, when it comes to dry suits—they dive cold waters. In addition, I own an older DUI FLX Extreme, made in the USA.

Webb and I have been having informal ongoing discussions about neoprene for several years. It’s a subject that is not well understood by many divers. So I thought I’d reach out to this veteran pundit of polymers and ask him to make his case. Here’s what the man had to say.

By my count, you have been in the diving industry for close to 40 years, and you always seem enthusiastic and positive. Where do you find your inspiration?

Ha! I was just speaking to one of the guys who does a lot of graphic design for us. We are not a fashion brand, but we are coming up with a new range of T-shirts. I said to him, “Dave, we really need to tap into where we live. California is a great example. There are so many great brands that are tapped into California and the lifestyle. But we live in an incredible part of the world here in Dorset. We live on the Jurassic Coast and are surrounded by seawater.

I think that’s what inspires me; it’s the environment here that helps us design the suits the way we do. If our suits can put up with the rigors of the Dorset Coast and the weather that we have here, then we are going to be making some pretty decent suits. That’s what drives us. You can’t help but be inspired every day when you wake up and traverse the causeway to come to work. We are very lucky where we are.

I’m going to have to come and visit you next time I’m in the UK for sure.

There’s phenomenal diving. I guarantee you!

Before we get into drysuits, I’d like to know what you think the biggest changes are that you’ve seen in the industry over the last 40 years?

Obviously, rebreathers have been the big change, although they got off to a slow start. I think they’ve revolutionized scuba. It’s been phenomenal. To see people getting into diving and going straight into rebreathers. Ten years ago, people didn’t think that would happen, and now it has. Of course, the continued commercialization of what was predominantly a recreational pastime has been going on the whole time. Has that been good for diving? I don’t know, but the move to rebreathers has been incredible.

It has. You know, judging from today, when we look back at the “Technical Diving Revolution” that emerged in the late 1980s/early 90s, you could argue it was really all about moving to rebreathers. It has just taken us a while to get here. As a community we first needed to develop and create the infrastructure for mixed gas diving, as a necessary step.

Let me ask you the same question about drysuits. What do you think have been the biggest developments in drysuit technology over the last 30-plus years since you started O’Three?

One word: neoprene! I think a lot of individuals are stuck in the Dark Ages and think that when it comes to neoprene, we’re still dealing with a fairly thick robust material that was invented back in 1930 and hasn’t changed since then. Whereas the truth is that neoprene compounds have gotten better and better and manufacturers have gotten better at making thin neoprene drysuits that stay dry for long periods of time.

When we first started it was a 7 mm, or maybe a 5 mm drysuit if you were pushing the boundaries. Whereas now, we can produce a 1 to 2 mm suit that’s strong and robust and divers have a great time in them. Without a doubt, the biggest change has been the neoprene.

Ha! I was thinking you were going to say front zips, dry gloves and P-valves.

Yes, all great developments, especially now that dives run into hours rather than minutes. But if you’re not DRY and comfortable, you’ll not be in the water long enough to warrant using dry gloves or a P-Valve. As for front entry zips, they create as many issues as they solve. But that’s a subject for another day.

We’ve talked about neoprene before. Obviously, there are a lot of new divers who get exposed to neoprene for the first time with their wetsuits. But for many, that’s it. Most tech divers upgrade to a drysuit and go straight to a trilaminate without ever working with neoprene. What should divers understand about neoprene that maybe they don’t?

Whether it’s neoprene or trilaminate, we always say that we spend as much time talking about the under suit, the base layers, the thermal layers, whatever you want to call them, as much as we do the suit. If you get that combination wrong, for example, you get your neoprene drysuit but your under suit combination is wrong, you could have a nightmare combination.

It’s the same if you get it wrong with a trilaminate.

So, we tell people: don’t think neoprene is the devil. If you wear the right under suit, which means you wear a much thinner under suit, you can have a terrific time in a neoprene suit and be better insulated, because the neoprene gives you that installation with a much thinner base layer.

What that means for most people is that the buoyancy change, which takes into account that both the drysuit and the under suit, is minimal. Yes, there is a little buoyancy change in the neoprene drysuit but very little buoyancy changes in the under suit. And people tend to forget that. Whereas with a trilaminate, you’ve got no buoyancy change in the trilaminate but a huge variation in buoyancy in the under suit as it compresses, because it’s that much thicker.

The air, err gas, in the under suit compresses.

Right, it’s the combination of the two—whether it’s shared between the neoprene and the under suit—or the trilaminate and a much bigger under suit. So labeling neoprene the devil, and trilaminate utopia, is simply misleading. I think you’ve experienced that.

I have. I own an O’Three 2.5 mm neoprene suit, of course, and two trliams and have come to appreciate that it’s the combined system when you’re talking buoyancy. Even though people buy the argument that neoprene is a great insulator, they have in their heads that it compresses at depth, and so they get no insulation at depth, and it will screw up their buoyancy. Which isn’t true with the new materials, correct?

No, it isn’t true. We’ve had some interesting conversations about this, even with the likes of some of our military users who should know better. If the suit starts off at 3 mm and it goes down to 0.5 mm, you’ve still got some insulation there. Whereas with the trilaminate suit, at the surface, at 30 or 40 m, there is zero insulation. It just keeps you dry.

Of course, the neoprene expands again during ascent, and again, people think it’s going to send them into a tailspin and they’ll come accelerating to the surface. But if you’ve done your buoyancy checks, there shouldn’t be any issues. The neoprene is going to expand at 10 meters and shallower just where you are going to need that extra bit of insulation for the long part of your hang.

I know you make several sizes of neoprene. I want to ask you about them: the Ri 100 (1 mm), Ri 2-100 (2.5 mm) and the MSF 500 (5mm). But first, I noticed on the website that the Ri 100 isn’t there anymore. That’s the crushed neoprene, right? You have discontinued the line?

The short answer is, yes we have. And credit where credit is due; that suit was inspired by DUI (Diving Unlimited International) and the materials that they made many, many years ago.

Yup, I used to have a CF200 back in the 1990s. That was “The Tech Drysuit” of the day and the team at Capt. Billy Dean’s Key West Diver all had them. DUI still makes them, but I believe they use a different neoprene these days.

Exactly, credit where credit is due. I’m not going to get into any politics there, but crushed neoprene is not the material that it once was. And our RI 100 material was brilliant. When it was on point, and our manufacturer was ticking all the boxes, it was great. But to make that material requires too many processes, and there are a host of variables. As a result, the tolerances that we were getting made it difficult, if not impossible, to manage and work with. We decided to put it on the back burner. Ironically, we replaced it with a trilaminate suit, which may seem odd, as we have a long history as a neoprene manufacturer.

I want to talk about your new trilaminate suits, but first I have a few more questions about your neoprene suits. What is the difference between the Ri-2 100 (2.5 mm) and the MSF 500 (5 mm) in terms of diving characteristics? Obviously, it’s thicker neoprene, but what does that mean operationally from a diver point of view?

The 5 mm neoprene suit has been our bread and butter. Think of it as a modern version of the good old-fashioned 8 mm suits, which were great in their way, but things have moved on. You’ve still got a nice piece of neoprene wrapped around you. It can fit a little bit better because the neoprene is the thing that’s giving you the insulation. You only need some very thin base layers underneath it. Nothing big and bulky. And people, shall we say from a more traditional neoprene background, will like that type of fit and feel. Again, because the insulation is in the neoprene, we can cut it slightly closer, err tighter.

The result is that because it’s fitted better and only needs a thinner base layer, the buoyancy variation of the 500 is likely less than that of a loose fitting trilaminate with really thick under suits. It’s more streamlined, so you’re pushing less bulk through the water. It does change at depth. It will lose its thickness at 30-odd meters. It will be half the thickness. But again, if you’ve done your buoyancy checks and you’ve got that nailed, it shouldn’t be an issue.

Interesting!

The fact is, over the last 33 years, you’d be surprised by the number of people who’ve come to us and said, “Do you know what? I’m wearing less lead with the 500 than I was with my big trilaminate and under suit which was bulky underwater.” They’re wearing less lead with it. The proof is in the pudding, you know?

What about the 2.5 mm suit?

It’s a completely different rubber compound, so it compresses much less. It is going to be colder because it’s not five mil, but you have to put a thicker under suit on underneath it, and you make up that difference in the insulation. It’s a nice combination between under suit and neoprene, and you share the responsibility of the insulation between the two elements of your drysuit.

In the warmer months, for people who still want to wear a drysuit, we sell a lot of those to people who dive and instruct in the Red Sea, and they’ll have a two point five mil neoprene. It’s not so onerous when it’s a little bit warmer. They’ll wear some Lycra leggings underneath it and a T-shirt and carry on diving and then throw maybe a slightly thicker under suit under it. In the winter, they will bring it back to the UK and dive with the appropriate undersuit. It’s a bit more versatile across a wider range of temperatures.

My first drysuit, back in the day, was an SAS neoprene suit with a back zip and all neoprene seals. Remember those? I loved it compared to a wetsuit. OMG! California has cold water. I forget if it was a five or an eight mil. It was probably an eight. Because it was old and that was what people did back then.

We are still making the odd eight mil neoprene drysuit today. And we still make a 7-8 mil hood-attached jacket and long john or farmer john for commercial scallop divers. They love it. They love that feel of a wetsuit. Okay, they’re not diving in January and February in the UK, but…

Do new UK divers go to drysuits right away? Is that pretty typical?

It’s becoming more typical. I’d say it’s probably 50-50. But I’ve got no statistics to back that up. Again, 10 years ago there was definitely, “get yourself into a wetsuit or a semi drysuit, get a year under your belt and then get a drysuit.” But I would say there’s definitely more push to go straight into a drysuit. And why not? If you’re taught properly and you understand things, then great.

I’m still a bit old school and would rather see people dive for a year or so in a wetsuit to just focus on their skills rather than have to worry about a drysuit. Because they can bite you in the bum if you drive them wrong. Fine-tune all your skills and then jump into a drysuit.

That makes good sense. Over the last five years, O’Three has added trilaminate suits to their product line. What was your motivation?

First and foremost, we don’t necessarily always make decisions on the best business practices, because we’re passionate about it. I’m not going to pull any punches; it was a business decision. Neoprene can’t be everything to everybody. We came back from DEMA after listening to many of your fellow tech compatriots saying, “Do you make a lightweight front entry trilaminate?”

After saying “no” to a not-insignificant number of people, we came back on the plane and, after a few whiskeys, said, “We’ve got to master this trilaminate.” And that’s what we did.

It’s been really successful. We didn’t run before we could walk. We knew about trilaminate, but we’d never put one together until four to five years ago. It’s been an interesting journey. In fact, we are just about to expand the product line—the production facilities here at our base in Portland, Dorset. It gives us another bite of the cherry, or slice of the pie, so to speak, and they are backed up with the same customer care and product detail and attention to detail that we’ve done with the neoprene. People are starting to respond positively.

Have you done anything special with them? Anything unique to O’Three?

We can offer many customizations. Gear and suits can’t be all things to everybody, but we can offer many options. In order to attach neoprene seals directly to the suit, a lot of people are moving to ring systems, which we can do as well. We tried to keep the front of the suit fairly clutter free, so we haven’t double-zipped the front entry. We offer an Aquaseal YKK plastic zip running across the front or the BDM medium duty metal zip running across the front, and we’ve come up with a nice clean way of covering the zipper and protecting it without applying another zipper over the top of it. Generally, that is A: a bit of a ball ache to the manufacturer, and B: When they do break, because they will break, they are very difficult to replace. So, we just kept that nice and clean and clutter free.

Sounds well thought out. I will take a look at your trilaminate at DEMA this year in Orlando. Will O’Three be coming to DEMA?

To be honest, we’re having a good time selling suits directly to the people in the US. The days of going through a distributor are gone, we feel, and DEMA is quite expensive, as you know. So, the jury is out yet as to whether we are going to be there. We do have a nice following over in the U.S. A couple of years ago, we added an influencer named Jared Leisek, who hosts “Adventures with Purpose,” and that’s really boosted our reach.

It’s been quite a revelation for our business that had relied on all the traditional ways of advertising and word-of-mouth. So that’s been very, very interesting. He’s coming up with some good results.

What would you say is O’Three’s key differentiator, err secret sauce. Is there something that you feel like, “this is our core that we do better than anyone else”?

I’m sitting here and not really racking my brains because I’ve got the answer. I think the main thing with a company like ours is that drysuits are 98% of our business, and if we don’t get it right, we don’t have a business. So all of our focus and all of our energy is on making sure that we make the best possible suit we can. And if things do go wrong, and they do for every company at some point, we’ve got to give people five-star service. If the shit does hit the fan, we’ll move heaven and earth to put things right for people. I think those two things are what sets us apart.

That makes good sense. I see on your website that you stress quality and customer service as your key focus. I know for me; my Ri 2-100 feels like a Mercedes or a Porsche—the quality is just evident. But of course, everyone says, ‘Yes, we make a quality product,’ but what does that actually mean when you say we make a quality drysuit? Talk to me a little about that.

Again, I think you have to look beyond what’s staring you in the face, which is a sheet of neoprene or a sheet of trilaminate material and some glue and some tape. We’re always thinking about the end-user and how would we want to be treated? What sort of product would we want to buy? And I think that drives us when we’re putting things together.

We do a lot of manufacturing here in the UK. The entire trilaminate line is made here. We have manufactured in the Far East for many, many years, and though other vendors do as well, there are definitely differences.

That’s in the specification, and the fact that we go to the factory during every production period. So, perhaps it’s just a little bit more attention to detail. We are not making units for anonymous users. We slow things down.

Putting a wetsuit together is fairly easy, but when you’re talking about drysuits, if the seam is not spot-on from start to finish, we’re going to have failures. Maybe not when we initially leak test it, but six months down the road we’re going to have failures. And so, we need to give that attention throughout the early stages. For us, the tape on the inside of a suit is just there as an insurance policy. It’s not an integral part of making sure that the suit stays dry—that’s been done before we put the tape on. Make sense?

“What sort of product would we want to buy?” Yes. I can totally relate to what you said from my experience making aquaCORPS back in the day, and now InDepth. What sort of story do I want to read!

Let me ask you about neoprene, because as you have alluded to, all neoprene is not the same, right? There are grades of neoprene, levels of quality.

Exactly. The market starts at the very, very bottom, with neoprene products in Walmart and discount stores; the neoprene is neoprene in name, but there’s very, very little neoprene in it. It’s a mass-produced material that won’t stand up to UV or to compression. It’s great on the surface, but the minute that you put it under water, that is under pressure, it’s a different ballgame.

It’s important to make sure that the neoprene compound that’s being used reflects that. The surfing industry has been a major driver of neoprene technology. There are many more people surfing and doing surface water sports than diving, and for them compressibility is not an important issue.

When we speak to neoprene manufacturers, we say it has to be a dive-grade neoprene. And there are different grades within that genre as well. You have to choose carefully and make sure that you use certain neoprene on different areas of the body. For example, the Ri 2-100 uses four different neoprene compounds. The nylon linings have an impact as well. There’s more to it than meets the eye.

I know you have quite a few ambassadors. The Wet Mules are one. That’s a group that I follow and they’re doing some amazing diving as you know in Pierce Resurgence and other places. Rick Stanton is another, right?

Rick Stanton has been a customer and a friend for years and years. He quietly does his thing, as you know. Obviously, he’s getting some international recognition now, and I think Ron Howard’s film, Thirteen Lives, is coming out in November. So that’s going to put him and the rest of the guys on another pedestal, and quite rightly so. But he’s one of those people that just gets on with it quietly. As does John [Volanthen]. [Ed note: author of Thirteen Lessons that Saved Thirteen Lives]. John was in the shop last week. They never expect anything and are always happy to pay. And we have to tell them, you’re not paying. They are such great unassuming guys.

They’re heroes in my book.

They are phenomenal.

I have another technology question. I was just up in British Columbia and I noticed that all the locals up there, or at least most of them, were diving “heat”—electric heating systems. Many used the SANTI system, and there was another company called Versatile Technology that makes a vest with batteries. What are your thoughts on electric heat?

It’s a bit like the Ri 100. We made a heated under vest many years ago. Again, cutting to the chase, we stopped doing it about four years ago because the market was so small back then. SANTI is doing a great job BTW. I would say that they’re probably the market leader.

It seems like, yeah. DUI had a product for a while, Blue Heat, but they withdrew it. I don’t think they offer that anymore.

It’s such a small niche market. We’re still making our heated vests for the British Special Boat Service (SBS). And we’ve had that contract with those guys for 20 years now, nearly. But the general public, being diplomatic now, just don’t apply the same level of care. It was a difficult product to support because of electricity and water. There’s a lot that could go wrong, and you do need to look after it. So, we decided it’s not our bread and butter, and we decided to leave that to the bigger boys. SANTI is there.

Of course, heat is not just for tech divers but anyone diving in really cold, single-digit water, right?

Going back to the basics: If your drysuit and under suit are really dry, it’s much easier for your body to heat up the dry air. So, if you have that right and you’re still cold, then perhaps you should look at a heated suit. Because, dives are often more than an hour. It can be two, three, four hours. The Pierce Resurgence guys [aka Wet Mules], bloody hell, they’re in the water for 15 hours.

Yeah, in 6°C water. Oh my God. You make heated under suits for them, right?

Yes, some of the Mules are using them, and some are using their own iterations of systems that are out there. They’ve got to bring anything they can.

Our heated under vest is a loom of wire, and the switch went through the inlet valve. We adapted a standard APEX non-swivel valve, and then we put the on-off switch there. The battery pack is attached outside of the suit. But I believe the Mules also have battery systems in their habitats that they can plug into. They’ve got an array of adaptations, whether it’s some of our vests that are still using and other bits and pieces. They’re quite a clever bunch of guys, and they’ll adapt things. Rick does that with his equipment too. They’ll adapt it and make it suit what they want, and they’re not afraid to change things.

I’m glad I asked you about that. Interesting. Just as an aside, I’ve been working with Harry [Dr. Richard Harris]. They are really pushing the limits of physiology on these dives and so we started looking at hydrogen—using hydrogen for the very deep portion of the dives. I organized a small hydrogen working group. Our focus has been to investigate how tech divers could use hydrogen breathing mixes to improve safety and performance. We focused on the Mule’s Pierce Resurgence dives as they were a great example.

How far off do you think they are from bringing it in?

Good question! They’ve got a ways to go. Ha! The problem is testing. Do you just say, “Okay, it sounds good in principle though it’s never been done before, let’s give it a try for real.” Ha! I have a great video of Harry, Dr. Richard Harris, imitating Clint Eastwood’s Dirty Harry character, going, “Well punk, are you feeling lucky today?”

They are looking at hydrogen, which is, of course, half the molecular weight of helium, because at the depths they are diving (to 250 m/815 ft and beyond), the density of the breathing gas is around seven plus grams per liter (g/L)—quite a bit above Drs. Simon Mitchell and Gavin Anthony’s maximum, do-not-exceed limit of 6.2 g/L. Danger, danger! Any exertion at those pressures and gas density, and you’re liable to buy the farm!

I’ll never forget—I think it was at OZTek maybe ten years ago. They showed footage and were explaining about how heavy the gas was and how difficult it was to push around the loop. And everybody in that auditorium was breathing hard as Harry was talking.

Ha! It’s not a trivial problem to fix. They are actually considering ways to help move the gas around the loop, for example, like those used in Continuous Positive Airway pressure (CPAP) machines for sleep apnea, which pressurizes the gas—well in this case air—slightly above ambient.

How would they decompress from hydrogen? Are there any tables?

Another good question! According to noted decompression physiologist, David Doolette, who was in our H2 group, that’s the least of their problems! There are a number of critical issues that the Mules are going to have to sort out to dive hydrogen.

First, it’s explosive when mixed with more than 4% oxygen, hence only useful for deep depths. For example, a 4% oxygen mix at 250 m would yield a PO2 of 1.04—shallower than that and you’re not going to have efficient decompression. Also, H2 has five times the heat conductivity of helium, so they will likely have to heat the gas. Of course, heated breathing gas is standard for commercial and military SAT divers. It’s a crazy and yet intriguing idea.

It sounds like something that Elon Musk needs to get involved with!

Right?! Instead of buying Twitter! Ha! They need a billionaire behind them for sure, if only to afford the testing that will be required. But it’s a real thing. I think at some point it will happen. The idea is to improve the safety and performance of conducting a 300, 310 meter dive, something like that—1000 feet over current methods. And of course, the word “safe” is really relative when you’re talking about doing surface-to-surface bounce dives to those depths.

Did I ever tell you how we connected with the Mules?

No.

It was through Rick Stanton. Harry mentioned it in an interview in “The Rescue.” He said something like, “This quiet unassuming English guy turned up who we had never met before, with a dry suit that looked like the best part of 20 years old.”

That dry suit was a 4mm neoprene that we used to make and the guy was Rick Stanton. That’s how O’Three came on the radar of the Wet Mules. That was about 15 years ago now. A couple of years into our relationship with those guys, I’m not sure whether it was Harry or Craig, but one of them told me that switching to neoprene (the Ri 2100) brought benefits that they were not aware of at the time; they just wanted reliable, dry, drysuits.

The benefits were the combination of streamlining and insulation that the neoprene suits gave them. The combination of those benefits reduced the effort, the exertion required to carry out those dives. They told me that the switch from trilam to neoprene was a game changer.

That makes sense. I remember Craig talking about the dangers of any exertion at those depths where just moving gas around the loop required an exertion because of the density of the gas. He said if you’re breathing is not calm and controlled, then you’ll soon be “behind the eight ball,” and things could go rapidly out of control. That’s what caused David Shaw’s death at Bushmansgat—respiratory insufficiency. Sadly, his video camera recorded his demise—respiratory insufficiency.

Sorry to get us off track Sean. I just find this stuff fascinating. So looking into the future, what are your plans for O’Three going forward?

We’ve always been lucky from a staffing point of view. We have a few people that have been with us for a long time, but we have also got a great young team coming up. We’ve managed, not necessarily by judgment, but by luck, to reduce the [average] age of the team considerably over the last couple of years. And that’s a good thing for my partner Marcus and I going forward. We are hopeful that O’Three will continue. With the young team we have now, there’s no reason why the company couldn’t go on for another 25, 30 years. So, from a business point of view, we’re strong.

I think, being really honest now, that some of our products have been designed to reflect how we think they should be built. But we need to look over our shoulder and realize that many of the new people coming into diving today want a slightly easier ride, if that’s good terminology. They want products that are easier to use. They might not perform as well, but then they are not doing the kind of diving that we expected them to do.

You’re speaking of recreational and or tourist divers.

That’s right. So we’re gearing up some products more suitable for the recreational diver because that is where the biggest part of the market is right now. We probably need to create a line that’s more user-friendly, shall we say, to get on and off. They might not perform as well, but these guys aren’t the Pierce Resurgence guys and they aren’t the Rick Stantons of the world.

There are a couple of brands out there that have done well in that market, and we need to look at that going forward while not compromising what we do best, which is hopefully creating high quality products that will keep people dry and warm for many hours in temperate waters.

Thank you Sean. I wish you and your team the best of luck!

Michael Menduno/M2 is InDepth’s editor-in-chief and an award-winning journalist and technologist who has written about diving and diving technology for more than 30 years. He coined the term “technical diving.” His magazine “aquaCORPS: The Journal for Technical Diving” (1990-1996) helped usher tech diving into mainstream sports diving, and he produced the first tek.Conferences and Rebreather Forums 1.0 & 2.0. In addition to InDepth, Menduno serves as an editor/reporter for DAN Europe’s Alert Diver magazine, a contributing editor for X-Ray mag, and writes for DeeperBlue.com. He is on the board of the Historical Diving Society (USA), and a member of the Rebreather Training Council.