Equipment

Divesoft Is At It Again with New Tools for Tekkies

Czech Republic-based Divesoft upended the helium analysis market with their patented accoustic-based helium/oxygen analyzer, which they launched in 2013. What are they up to now?

by Michael Menduno

Divesoft was born when Czech Information Technology (IT) entrepreneurs Ales Prochaska and Lucie Šmejkalová, who ran a successful online banking software business for 20 years, decided to forgo the corporate life and apply their considerable expertise to their shared passion for diving. Beginning with an innovative helium-oxygen analyzer, the “He/O2 analyzer,” which uses a patented (2012) acoustic helium sensor that Prochaska created and built for himself and his friends, the pair of brainiacs went on to create the Liberty Rebreather, which is arguably one of the most fault-tolerant systems on the market, along with their line of Freedom dive computers.

After launching the company in the spring of 2013, Prochaska, Šmejkalová, and their team exhibited at the Diving Equipment & Marketing Association (DEMA) in 2014. I was there and remember the crowd of tech divers huddled around their booth, peppering the Divesoft staff with questions about the unique fault-tolerant equipment on display. I was one of them.

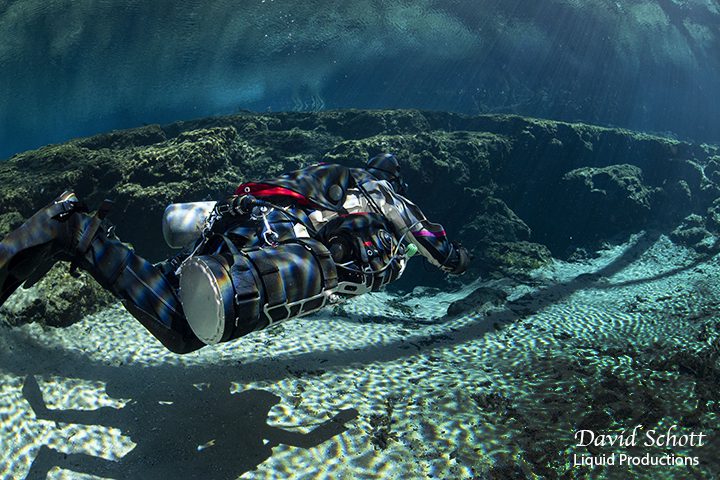

Since that time, Divesoft has grown to become a serious contender in the global rebreather market, offering both back mount and sidemount versions of the Liberty. The company has attracted numerous high-profile users like Canadian filmmaker and educator Jill Heinerth; Polish deep cave diving record setter Krzysztof Starnawski, award-winning U.S. cinematographer Becky Kagan Schott, Italian explorer Edoardo Pavia, UK’s man in the Yucatan Steve Bogaerts, and many more. This summer, the innovative equipment makers introduced their “Analyser Solo,” a new lightweight, easy-to-use helium-oxygen analyzer. We caught up with Prochaska over the summer. Here is what the banking-software-guru-turned-tech-diving-inventor had to say.

InDepth: You describe your He/O2 analyzer as the “foundation stone” for the company. What motivated you to create this analyzer? Of all the diving equipment you could create, why a He/O2 sensor?

Ales Prochaska: When I started diving helium blends, there wasn’t an easy-to-use analyzer that could show me the complete blend composition in a single step. So, I created the analyzer mainly for my own use. When I commissioned the electronics board, I had ten of them made, in case any fellow divers were also in need of an analyzer. Turns out they were, and the whole stock of analyzers sold within two days.

I understand you use a standard electrochemical oxygen sensor in the analyzer. How did you come up with the idea for an acoustic helium sensor versus a chemical sensor? It seems like a brilliant solution and, in retrospect, an obvious approach in some ways. Divers are, of course, very aware of helium’s acoustical properties from listening to our Donald Duck voices!

I researched all the physical properties of helium I could think of. There were many pages to go through. I studied them and tried to imagine a sensor based on each. And the acoustic principle won, being easy to implement and very accurate.

How does it work?

The helium content is determined based on measuring the speed of sound in the analyzed mix. The speed of sound depends on the content of helium and oxygen, and the temperature of the mix. The dependence of the speed of sound on pressure is small and can be disregarded under normal atmospheric pressure.

Did your educational background help you create the analyzer?

Yes, in the case of the analyzer, I found my previous studies in engineering, electrical engineering, and software engineering to be very useful. Skills from all three fields were needed to design and manufacture the analyzer.

What was your and Lucie’s diving background? Are you both tech divers?

From my first diving course, I realized that technical diving was the direction I wanted to follow and explore intensively. Lucie, on the other hand, is not as attracted to technical diving or caves. She prefers a dive in the warm tropical seas among the coral fish!

How long did it take you to build that first analyzer?

The first analyzer was sold in 2004, but the development began a little earlier.

And you have the patent. Brilliant! What benefits does the acoustic sensor bestow on users compared to other chemical-based He analyzers?

Yes, the sensor is patented. The acoustic principle used allows fast and efficient measurements, even on flowing gas. It’s also as easy to use as a conventional nitrox analyzer, and I think that was the biggest benefit of our analyzer.

Divesoft just introduced the “Analyzer Solo.” How does it differ from its original He/O2 Analyzer?

The Solo Analyzer is a lighter and more simplified version of the He/O2 Analyzer. However, the original is still produced because it allows the attachment of additional equipment such as a pressure sensor and others alike. The Solo has no plug-in connector.

What came next; the Liberty rebreather or the Freedom dive computers or both?

They were supposed to launch simultaneously because the computer and its software were developed at the same time as the Liberty control unit (with which it has a common base), but we managed to release the dive computer a little earlier.

What year was that?

We launched the company in 2013!

How did you go from a He/O2 analyzer to a rebreather, the flagship of your company? What was your motivation to build a rebreather, or was that always the goal?

The motivation to develop Liberty was similar to that of the analyzer. We wanted to dive with a rebreather, but none of the devices on the market at that time had all of the features we found important. We had a clear idea of the qualities a rebreather should have and knew we could design it. This was in and of itself a great motivation to try.

Necessity is the mother of invention! What made you think you could build a rebreather in terms of expertise and experience? How did your earlier work in IT inform your design ideas and implementation?

At first glance it doesn’t appear as such, but the fault-tolerant rebreather is an extensive software masterpiece above all. We had a lot of experience with fault-tolerant systems through our IT and even our underwater backgrounds. At one point, we had developed a software that was supposed to be perfectly resistant to failure. When Prague was hit by the huge flood in 2002, it destroyed the main data center. The system we designed, however, transferred the activity to a backup center and continued working as if nothing had ever happened. Since then, we knew that we wanted to pursue a system that could be sunk underwater deliberately, not just during a flood.

Wow. Very cool. Clearly “fault-tolerance” is part of the DNA of your rebreather. Was that your starting point, then, for your design?

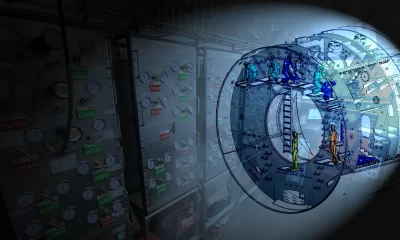

Yes, that was a clear goal from the beginning. We knew that other rebreathers were not completely fault-tolerant. Their standard solution was to go into restricted safe mode or report an error and wait for the user to deal with it. Our intention was to develop a rebreather that, in the case of a control electronics failure, anything from discharging the battery to interrupting the solenoid coil, would continue to operate without any restriction. In technical diving, there may be situations where several problems gradually accumulate and prohibit divers from emerging in less than a few hours. In those cases, a rebreather that remains working despite having a defect may be necessary.

Were dive computers just a logical add-on?

Yes, once we had mastered the rebreather control software, including the decompression model and the waterproof rebreather handset, it would have been a shame not to use it to design an independent diving computer. All we needed was to cut the rebreather cable, refill the battery and the computer was (almost) finished. (Ales smiles.)

Talk to me a little about having four O2 sensors in the unit? How does that work?

The number of sensors is closely related to the fault-tolerant properties. The standard number of sensors is three, sometimes the ‘3 + 1’ or ‘3 + 2’ arrangement is used, where the added sensors serve as an additional check on the functioning of the three main sensors. But Liberty has two complete, full-featured control units, each with its own sensors. That’s why we used four sensors, because this number is easily divided by two [Ales smiles]. Of course, this does not mean that each control unit works with only two sensors. The units keep communications with one another, and both are aware of the measurements of all four sensors.

I remember from Rebreather Forum 3.0, Nigel Jones, who worked with Poseidon, said that three sensors in a “voting logic” algorithm do NOT offer true redundancy, and in some cases offers much less redundancy than divers imagine. Does your algorithm offer something stronger? Please explain.

The degree of redundancy depends on the evaluation algorithm i.e. “voting logic.” If properly designed, more sensors will always be more secure. At Liberty, we monitor not only the instantaneous values of the sensors (plus the elimination of the obviously defective, for example, flooded sensors), but also their course over time. We know when the system adds oxygen and how much and the depth and volume of the breathing circuit; from that we can calculate how much the sensor should measure. From the reaction of the other sensors, we can also manually add oxygen or diluent. We also know how and how fast the sensors should respond to depth changes. From all of this, we can identify the faulty sensor and exclude it from the measurements. And, of course, the system always informs the diver of such an event, as they have the final say in how to proceed.

Fascinating! It sounds like the Liberty uses some of the same principles that Bill Stone used in designing his “Active Validation” approach in Poseidon rebreather, that is comparing instantaneous sensor values with what you expect them to be.

But what Nigel Jones said, of course, still applies. The diver should never assume the control unit will solve everything. The control unit solves only what it is programmed for, so, for example, the quality of the sensors and their replacement must be supervised by the divers themselves. There was a case where a diver had two faulty sensors and one good sensor in a rebreather, and the control unit ignored the values of the correct sensor. The unit decided based on two faulty sensors, which ‘outvoted’ the right sensor.

Why two helium sensors? The FHe is not going to change during the dive, is it?

Helium concentration changes during the dive because the oxygen concentration changes. The more oxygen, the less diluent and thus less helium. This logic could also be reversed and the oxygen concentration could be calculated by measuring the helium concentration (with a known diluent composition). Thus, the helium sensor not only serves for the correct calculation of decompression based on the actual He content, but could be used in emergencies to measure the oxygen concentration under certain conditions. There are two He sensors, with each control unit having its own.

Ah of course. In the loop! Clever! Dual computers as well, right?

Of course, a duplicate computer is necessary for fault-tolerant devices. Each computer has its own battery and is connected to the other only by a data bus. The data bus is, of course, waterproof and short-circuit-proof, so no conceivable failure of one computer could affect the other.

I believe your back mount CCR came first, yes? What motivated you to create a sidemount unit as well?

Back mount CCR came first because it was and still is the main type of rebreather arrangement. Sidemount was the logical successor of the back mount. It uses the same body and a variety of other parts as the back mount but is horizontally mounted on a special rack. The need for sidemount originally came from cave divers, so we wanted to provide them with the opportunity to use Liberty in this arrangement as well.

Is a sidemount CCR a specialized niche product, or do you think it will replace or at least equally compete with back mount CCR?

Liberty sidemount is a complete rebreather, including bottles with diluent and oxygen. It can be used not only for cavers, but also as a backup rebreather, handed to another diver without having to switch hoses from off-board gases.

The number of divers who use sidemount as the main unit during diving is increasing. The sidemount’s arrangement has some advantages over the back mount and there are now known and proven procedures as well as technical equipment for diving with sidemount. Its growth is inevitable. While I do not expect the back mount to be replaced altogether, it seems the usage of sidemounts is increasing and many divers will choose it as their main unit.

What would you say are the critical issues right now in CCR diving?

The biggest problem is divers pursuing rebreather diving without adequate training. They see the usage of rebreathers increasing and think that diving with a rebreather is a common thing. But the fact is that diving with a rebreather is still more demanding in terms of skill and self-discipline than an open circuit, and divers who dive with a rebreather without undergoing any type of training are putting themselves at risk.

Would you say CCR diving is getting safer?

It is a little safer, especially since divers, instructors, and rebreather manufacturers are taking lessons from past accidents to try and avoid them. (Similar to the efforts of those in the auto and aviation industries.).

I see you have just added Synchrony Bank financing option for purchases of Divesoft gear. How did that come about? Has financing been a problem for dive consumers?

Synchrony Bank has been funding our products since the beginning of August solely for the US market where rentals are popular and widespread. We wanted to accommodate customers purchasing our goods by credit card.

Where is Divesoft headed? Do you have a collective vision for the future? What’s on the horizon?

We want to be innovators in the field of equipment for technical divers with a significant overlap in the field of recreational diving, of course. In addition to analyzers, our main domains are still rebreathers and diving computers. In these areas, we are already in development and planning stages for major improvements and innovations. We are currently preparing several innovations to be launched in November 2019 at DEMA, followed by BOOT 2020 in Dusseldorf. Stay tuned for those. [Ales smiles]

Divesoft has been sponsoring the exploration of Hranice Abyss. Are there other projects that Divesoft is sponsoring as well?

We sponsor the Greek Seahorse Rescue Station Hippocampus Marine Institute, as well as Czech police divers during mine clearance operations in the waters of the Sava, Una, and Drina rivers in Bosnia and Herzegovina. Last but not least, the Hranice Abyss.

Thank you so much. You have taken a unique approach, and it’s evident that it is really paying off for you. Congratulations!

My pleasure.

Read about their team’s exploration of the Hranice Abyss

Dive Deeper:

Aleš Prochoaska’s patent: Device for measuring oxygen concentration in gas mixtures containing helium and/or hydrogen

Michael Menduno is InDepth’s executive editor and, an award-winning reporter and technologist who has written about diving and diving technology for 30 years. He coined the term “technical diving.” His magazine “aquaCORPS: The Journal for Technical Diving”(1990-1996), helped usher tech diving into mainstream sports diving. He also produced the first Tek, EUROTek, and ASIATek conferences, and organized Rebreather Forums 1.0 and 2.0. Michael received the OZTEKMedia Excellence Award in 2011, the EUROTek Lifetime Achievement Award in 2012, and the TEKDive USA Media Award in 2018.

Dive Deeper:

Forbes Magazine article (In Czech):

I bez moře. Manželé, kteří v Roudnici vyrábějí potápěčskou techniku

In English:

“Even without the sea. Spouses who produce diving equipment in Roudnice”