Equipment

The RB80 Semi-closed Rebreather: A Successful Exploration Tool

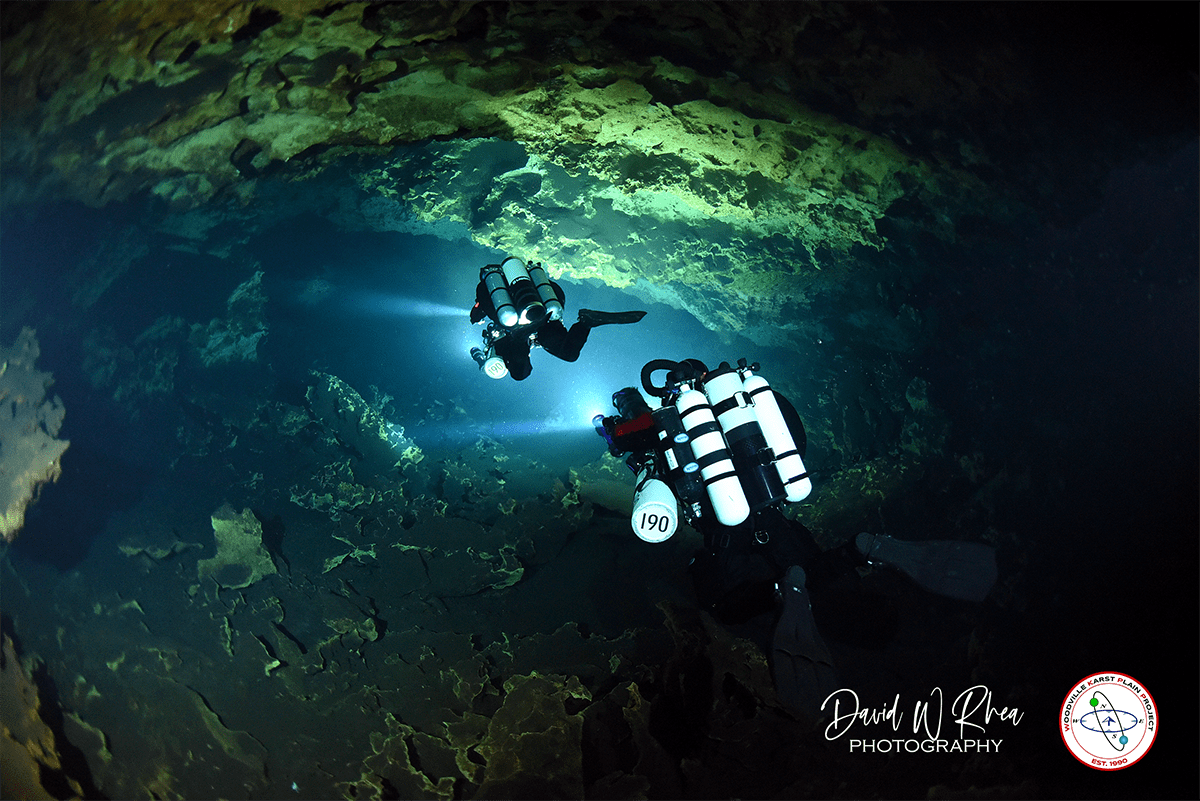

What rebreather has arguably logged the most exploration kilometers since its market introduction in 1998—an estimated 160 km plus (100 miles plus for you Imperialists)—and continues to rack up the klicks? It’s Halcyon’s RB80 passive-addition, semi-closed rebreather. Here WKPP greybeard and RB80 instructor trainer David Rhea reports on the RB80’s history, design & workings, training, and he offers the lowdown on its new sidemount progeny, the RBK. Looking for an electronics-free, sidemount bailout rebreather? Halcyon may just have your number.

By David Rhea

Header image by David Rhea

Full Disclosure: Halcyon Dive Systems is a sponsor of InDepth.

In the early 1990s, the cave exploration conducted by the Woodville Karst Plains Project (WKPP) in the Woodville Karst Plains of Florida, especially Wakulla Springs, was becoming quite complicated. With dives averaging depths of 89 m/290 ft, with penetration being measured in miles, and decompression taking hours, it was becoming obvious that rebreathers would be necessary to move forward. In 1996/97, the WKPP began using a semi-closed circuit rebreather known as a Passive Variable Ratio-biased Addition Semiclosed Rebreather (PVR-BASR), nicknamed “The Fridge,” to extend their exploration and decompression obligations. This piece of equipment was a very large, bulky, and complex unit, and while it was uncomfortable above and below the water, the PVR managed to do what was intended and allowed for further exploration.

In 1996, a team of European explorers called the European Karst Plains Project (EKPP), who utilized the “Doing It Right” (DIR) techniques and philosophy of the WKPP, began using a semi-closed rebreather called the RB-2000. The unit was developed by the EKPP founder and director Dr. Reinhard Buchaly, who was inspired by the great success of French cave explorer Olivier Isler had at Doux de Coly and other cave systems using a custom made, triple redundant, semi-closed rebreather, the RI 2000 designed with the help of French engineer Alain Ronjat.

The RB-2000 unit was much smaller than the PVR-BASR, and utilized a very clever, intuitive, and reliable design. This design complemented the DIR philosophy used by both teams, and would become the choice for both groups moving forward. By 1999, WKPP explorer Jarrod Jablonski and Robert Carmichael, the owners of Halcyon Dive Systems, worked out a deal with Buchaly to have Halcyon manufacture, sell, and service an American version known as the RB80.

Designing a Semi-closed Rebreather

Being a cylindrical design 185 mm/7.28 in. in diameter, and 660 mm/25.98 in. tall —virtually identical to the size of an aluminum 80 cylinder—helped the RB80 get its name. The RB80 was designed to fit between the cylinders of a double tank configuration utilizing a specially designed frame, manifold, and switch block system. The economy of parts allows for maximum efficiency with only about 130 parts total.

This design complemented the DIR philosophy of maintaining all of the diver’s back gas for emergencies, utilizing stage tanks for exploration and decompression. The gas switches utilized the same procedures taught by Global Underwater Explorers (GUE) but instead of swapping regulators from the mouth, the diver plugs a special QC6 swagelok fitted hose from the stage bottle into a switch block that feeds the gas into the rebreather.

The stage bottle regulator is a standard open circuit (OC) configuration with the addition of one extra hose with a QC6 connector. The switchback also allows for a hose from the back gas to be plugged into the block in case of a stage failure or other emergency.

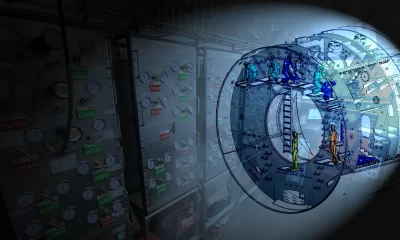

1. Dive/surface loop with non-return valves

2. Exhalation hose

3. Counterlung fore-chamber

4. Non-return valve to discharge bellows

5. Discharge bellows

6. Overpressure valve

7. Main counterlung bellows

8. Addition valve

9. Scrubber (axial flow)

10. Inhalation hose

11. Breathing gas storage cylinder

12. Cylinder valve

13. Regulator first stage

14. Submersible pressure gauge

15. Bailout demand valve

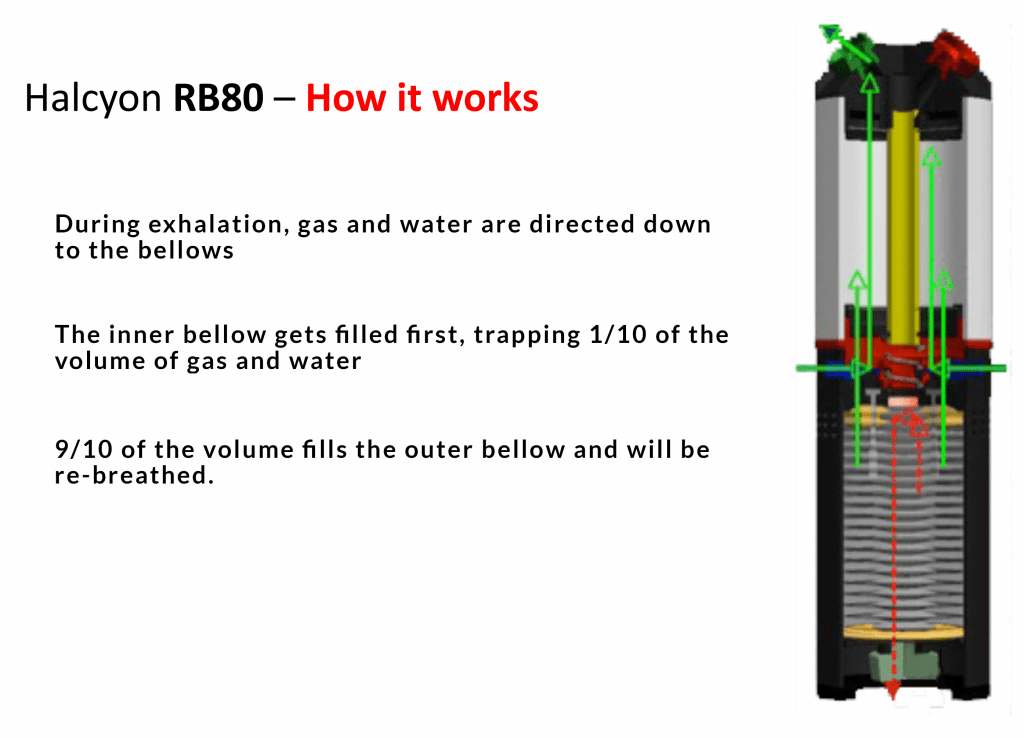

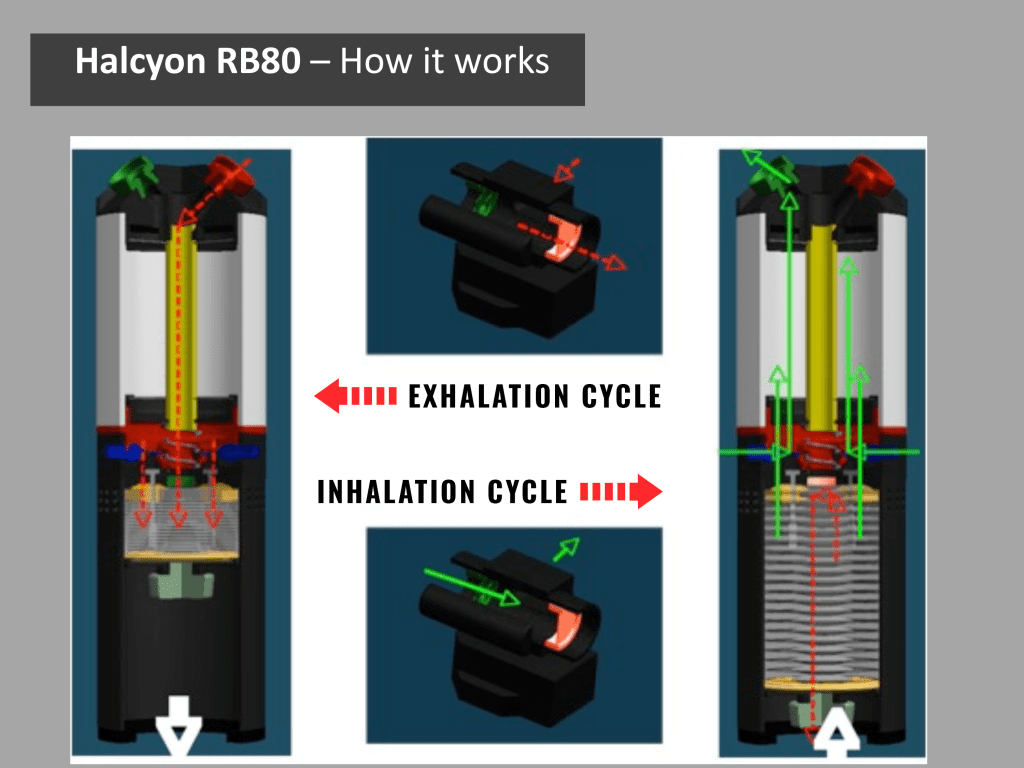

The vertical design of the RB80 has a very clever water removal tube that runs directly through the center of the scrubber bed and vents water along with a small volume of discharge gas. The unit is a passive addition semi-closed design, with no depth compensation and is tied to the diver’s respiratory rate. Roughly 1/10 of the respired volume of breathing gas is discharged into the water with each breathing cycle via the inner bellows and a familiar over pressure relief valve (OPV), commonly used on most dry suits. See Figure 2 and 3 below.

The RB80 utilizes a dual bellows counterlung system (versus traditional counter lungs), which reduces the loop volume each breathing cycle. When the loop volume is sufficiently reduced, it triggers the injectors made of components of an open circuit regulator that function quite similarly. Once the injectors fire, the loop volume is replenished with fresh gas. The unit has dual injectors for redundancy, which can be isolated at the switchblock if necessary.

The scrubber bed lies above the bellows in this vertical design and is manually filled by the diver before each dive. The scrubber is a 3.2 kg/7.05 lb design and will last approximately ten hours, based on more than twenty years of operational experience. Note that semi-closed rebreathers generally get longer duration on a scrubber given that a percentage of the breathed gas is expelled and replaced with fresh gas.

The mouthpiece design incorporates a bail out valve (BOV) allowing the diver to switch from the rebreather to OC at the turn of a lever conveniently located in the center of the mouthpiece block. A hose routed from the right post regulator of the back gas is always live and gives gas immediately once the lever is turned.

Assessing the Work of Breathing

New rebreather divers often state they feel the RB80 has a lot of breathing resistance. This is generally due to the fact that they are accustomed to modern OC second stages which deliver almost effortless on-demand breathing. Typically, modern second stages use VIVA (Ventura-Initiated Vacuum Assist) technology. This technology, along with the geometry of the second stage and the fact that the second stage is balanced, make for incredible light cracking effort. Upon inhalation, the initial cracking effort lowers the gas volume in the case, which pulls down the flexible diaphragm, activating the lever that opens the valve and allowing gas to flow to the diver. The VIVA then keeps the gas flowing at the same rate without the need for the diver to continue to draw on the regulator.

By comparison with the RB80, the diver is simply pulling the gas through a one-way check valve, drawing the available gas in through the right inhalation hose, beyond the valve, into the mouthpiece block, and into the divers mouth. This entire system of gas flow does not have any boost effect like its OC sister and therefore feels as if you are working hard when, in fact, it is quite effortless. As a “virtually” closed loop, one simply draws the available gas through the inhalation hose into the diver’s mouth, and then exhales out a one-way valve at the mouthpiece, back through the left exhaust hose into the breather where the gas is scrubbed of CO2, water is removed, and the gas is replenished.

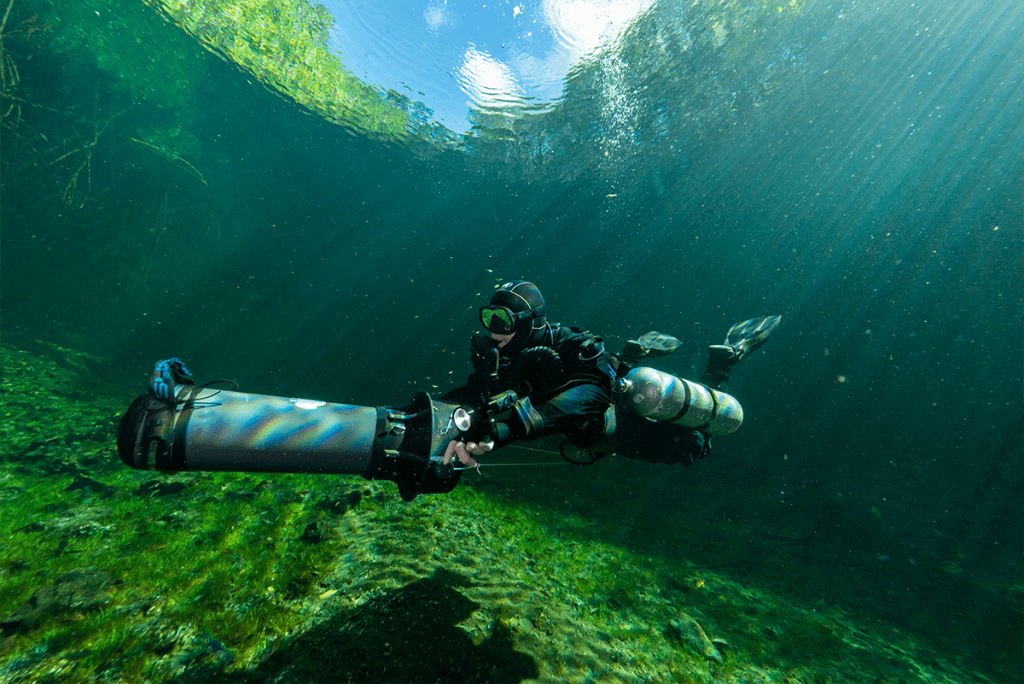

Similar to OC, the rebreather does vary in breathing performance based on the diver’s position. If you have ever stood on your head diving OC, you feel a change in performance, as the second stage is much deeper than the lungs. The RB80 historically being a back mounted rebreather keeps the unit at a slightly shallower depth than the diver’s lungs, making inhalation slightly harder and exhalation slightly easier. This difference is virtually indistinguishable; however, extreme head down or head up positions can seriously affect rebreather breathing efforts. When worn in a side mount or stage position, the unit is in equal position with the lungs, making for very easy breathing. Fortunately, when a diver is in near perfect trim, the RB80 performs best, as this is the ideal position for ease of breathing.

Extending a Diver’s Breathing Gas

The RB80 is a serious gas extension device, providing 8-10 times the gas mileage of OC. By rebreathing one’s gas and only losing 1/10 of each breathing cycle into the environment, the RB80 can take a single aluminum 80 cf/11 ltr stage bottle and turn it into roughly 640 cf/18m3, or the equivalent of eight AL 80s.

In cave exploration, we always start a project by setting up the cave with “safeties.” These are caches consisting of two bottles each equipped with a stage regulator complete with an OC second stage as well as a QC6 equipped drive hose to plug into the RB80, and a submersible pressure gauge (SPG). These bottles are placed roughly every 3,000-5,000 ft/900-1,500 m in the cave, and will remain there throughout the exploration. The safeties are checked by support divers prior to every push to ensure function and adequate gas volume. The bottles are properly filled and marked with the proper Maximum Operating Depth (MOD) gas for the dive, and they are labeled “SAFETY.”

With rebreather diving, it is paramount that adequate bailout gas be available in case of a single point failure on the rebreather. Rebreathers, while quite robust, have many single failure points, i.e., the breathing hoses, one way valves, OPV, the bellows in the case of the RB80, and even the diver’s mouthpiece. As mentioned, the injectors have redundancy and can be isolated in case of issues, and a spare mouthpiece is always carried by the diver in case of a serious tear or damage.

Any other single point failure could render the rebreather inoperable, forcing the diver to return and complete all decompression on OC, demanding eight times the amount of gas that had been used at this point in the dive. So, in addition to 100% of the back gas being maintained for bailout, cave exploration demands the discipline of staging the cave with safety bottles, safety scooters, as well caches of decompression gas, and proper support personnel.

RB80 vs. an Electronic-controlled Closed Circuit Rebreather (eCCR)

A variety of eCCRs are available by manufacturers. These units are extremely efficient, as no gas is lost from the breathing loop. The eCCR can be 25-50 times more efficient than OC. However, in addition to the single point failures listed above, which are common on all types of RBs, the eCCR, has additional concerns that prevent it from being a consideration for many cave exploration groups like the WKPP and GUE-affiliated El Centro Investigador del Sistema Acuífero de Quintana Roo (CINDAQ) foundation, which hosts the Mexico Cave Exploration Project (MCEP) in the Yucatan.

Most eCCRs have three oxygen sensor cells that must be meticulously maintained and work together with a solenoid and an electronic controller, using a concept called voting logic. Together with an oxygen bottle and a diluent bottle, the eCCR mixes the diver’s gas during the dive within a (PO2) set point range that is predetermined by the divers. By having three oxygen cells, the controller will side with the two that have the most similar reading if one were to start to read differently from the other two.

Unfortunately, voting logic is inferior to the gold standard—triple redundancy: main unit, back up, back up for the back up—and has been known to be incorrect i.e., in the case of a double cell failure. Discipline, and pre- and post-dive maintenance, are the key to maintaining good sensor reliability.

When diving an eCCR, it is necessary for the diver to constantly monitor the gas mix in their loop in order to ensure that they safely avoid hypoxia or hyperoxia. For an easy-to-see reminder that the unit is working within the safe limits set by the diver, most eCCRs rely on a heads-up display (HUD)— generally mounted to the inhalation hose—that shows a small series of lights indicating green for good, yellow for caution, and red for danger, in case the PO2 in the breathing loop is getting out of range. This is of course driven by a controller that gives real time PO2 that can be viewed on the diver’s handset. Most eCCRs provide at least one handset as well as the HUD to ensure proper redundancy.

One of the reasons many cave exploration groups like the WKPP strictly use the RB80 is its simplistic mechanical, reliable design. With the RB80, the gas is premixed into the stage bottles, and the back gas is always mixed for the MOD of the max depth expected to be reached during the dive. With the RB80, there is no gas mixing during the dive; the gas is plugged into the switch block similar to doing an open circuit gas switch. The gas is filled, properly analyzed, and the content label is attached to the neck of the bottle prior to leaving the dive center.

The bottles all have properly placed MOD stickers on two sides of the bottle for easy identification by both the diver and his team mates, plus a MOD sticker placed on the bottom of the cylinder that can be identified by teammates when being viewed from behind. In the water, the proper stage bottle is selected for the MOD, and the gas is safely plugged in at the proper switch depth, but only after the bottle has been properly identified, verified by the buddy, and the drive hose confirmed with the bottle that has been chosen, similar to open circuit gas switches.

The most dangerous thing about the RB80 (and semi-closed units in general), is the oxygen drop, especially in shallow water [See the Loop Gas calculations section of the RB80 page in Wikipedia]. Due to the fact that oxygen is being consumed during respiration, and gas is discharged from the inner bellows with each exhalation, the oxygen drops slightly with each breathing cycle until fresh gas is replenished from the injectors, typically every two to four breaths. For this reason, one must be cautious when using the RB80 at shallow depths (when the ambient pressure is low) or when using mixes with a lower oxygen fraction as a travel gas.

The drop in oxygen levels also means there is a slight increase in inert gas that remains in the loop and that needs to be taken into consideration for decompression. Both of these nuances of the RB80 are easy to calculate and adjust for prior to the dive.

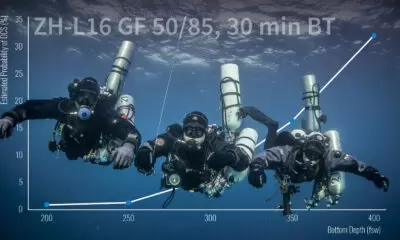

During RB80 training, both the oxygen drop and the increase in inert gas load are addressed and easily able to be factored in. The theory is discussed in an RB80 class, and software is available to easily do quick calculations. All of this can then be programmed into GUE’s Buhlmann-based desktop decompression program, DecoPlanner, for proper dive planning. Like most rebreathers, the RB80 has additional complexities requiring proper pre-dive assembly, testing, maintenance, and post-dive discipline.

Training on the RB80

The WKPP was established in 1995, and from the beginning, adopted a standardized approach to gear configuration and procedures. Initially, this approach was called “Hogarthian,” after early WKPP pioneer Bill Hogarth Main. Later, project director George Irvine added to the standardization and coined the phrase “Doing It Right,” or DIR, to represent this standardized approach. In 1998, Jarrod Jablonski founded GUE, which offered exploration-based training utilizing WKPP’s standardized approach and gear configuration. Once Halcyon started building the RB80, GUE began offering formal training. Currently they are the only training agency to do so.

From the beginning, GUE’s RB80 training has been exploration-based, with a heavy emphasis on failure-based training i.e. dealing with equipment failures as a team, similar to other GUE courses. Exploration-level cave diving has complex exposures that require divers to return from deep inside the cave, and then make a vertical ascent to return to the surface. With the addition of the RB80, divers are able to extend their penetrations exponentially, adding as much as 12-14 hours of decompression on some dives alone. Conventional rebreather training does not properly prepare someone for these types of exposures.

GUE divers have historically been required to take Fundamentals, Tech 1, and Tech 2 with a minimum of 25 dives at each level between classes prior to beginning their RB80 training. This is in addition to the Cave 1 and 2 level training and experience required to begin cave exploration. The investment of time, energy, and resources necessary to become a GUE/WKPP exploration cave diver makes for a very serious explorer who has the skills and experience necessary to conduct dives with this level of exposure. The failure-based training also builds the diver’s confidence, repetitive learning, and instincts necessary to safely explore.

One of the many reasons for the long term success of the RB80 has been this extremely regimented training by GUE’s four active RB80 instructors. In addition to the most intense and demanding rebreather training available, GUE RB80 students must purchase the unit prior to taking the training. This alone narrows the attendance to only the most serious explorer, as no rental option is considered.

Until fairly recently, GUE divers were the only ones using the RB80. Even then, only those willing to take the robust training who had an exploration mindset learned to dive the unit. Currently there are 150-200 GUE divers certified to dive the RB80. The discipline and attitude of these explorers has ensured that the RB80 has been responsible for more kilometers/miles of cave exploration than any other rebreather in the world. I estimate that more than 161.6 km/100 mi of cave passage has been explored using the RB80.

The discipline and attitude of these explorers has ensured that the RB80 has been responsible for more kilometers/miles of cave exploration than any other rebreather in the world. I estimate that more than 161.6 km/100 mi of cave passage has been explored using the RB80.

A Specialized Exploration Tool

For 30 years the WKPP has been mapping the underwater labyrinth of the Woodville Karst Plain, having mapped over 56,609 m/185,000 ft of cave passage with more than 35,189 m/115,000 ft below 58 m/190 ft. The RB80 has been one of the most vital keys to this success, including the world record dives in Wakulla and the following traverse. It is the only rebreather used for exploration on Woodville Karst Plain projects. Presently, virtually all exploration being conducted by the WKPP below 61 m/200 ft is exclusively done on the RB80.

Over the years, and especially during the Wakulla exploration heydays, one of the growing concerns was running out of scrubber material during the dive. On the biggest dives, the entire RB80 double tank configuration would be swapped at the deep portions of the decompression for a fresh ‘breather with smaller double five-liter bottles and fresh scrubber material. Note: an advantage of the RB80 over an eCCR is that the valves can be closed and the unit reliably stored underwater like a stage bottle for bailout. It can then be quickly turned on and dived.

In 2008, CINDAQ’s MCEP project also adopted the RB80 and has done countless hours of exploration in the caves of the Yucatán. Between January 2018 and December 2020, for example, MCEP exploration divers mapped in excess of 180,000 m/594,000 ft of new cave passage in Ox Bel Ha alone using RB80 technology.

As CINDAQ board member and co-owner of Zero Gravity Dive Center, Christophe Le Maillot, explained, “It is such a sturdy and intuitive unit. In all the years we used it, we have never had to terminate or cancel a dive because of a malfunction. It’s a real work horse!” Like their sister WKPP team, the MCEP exclusively uses GUE-trained RB80 divers for their exploration dives.

GUE divers have also utilized the RB80 for cave exploration projects in China, the Nullarbor caves in Australia, caves in the south of France, cave and wrecks of Italy including the Pantelleria project, the Alviela cave project in Spain, and other karst areas around the world. In addition to cave exploration, the RB80 has been utilized by GUE divers on the west coast for the ghost net removal, and by GUE wreck divers in Canada and around the world.

Introducing the RBK, a Sidemount RB80

In response to explorers wanting a stageable version of the RB80 as both a travel and/or bailout rebreather, Halcyon began working to develop a modified sidemount version of the RB80, called the RBK. The first version was called the RBK1 and after several years of modifications Halcyon produced two more revisions, the RBK 2 and the RBK 3, referred to simply as the RBK.

The overall diameter of the RBK is the same as the RB80, but by reducing the height of each section, the overall length of the unit has been reduced to 50 cm. Though the scrubber was reduced in volume to 2.4 kg/5.29 lb, the scrubber duration is rated for approximately eight hours based on user experience [See InDepth’s Rebreather Holiday Shopping Guide for add’l spec details]. Because of the smaller form factor, the RBK offers a 6-8:1 gas extension versus 8-10:1 on the full RB80.

The sidemount RBK has been used as a sidemount, travel, and bailout rebreather by both the WKPP and the MCEP, which has been testing and helping to refine various RBK prototypes since 2015. On recent long-range explorations through small passages, the RBK has proven to be an outstanding tool for shallower, long distance cave exploration. MCEP instructors are now working with the GUE board of directors and other RB80 instructors to develop a RBK sidemount training course, which should be available in the not-too-distant future.

New Non-GUE Users

Over the last few years, Halcyon has made the RBK available to select non-GUE divers. They have sold custom versions of the RBK to militaries around the world. In addition, they have provided RBK units to exploration divers from Karst Underwater Research (KUR), who have been using the RB80 as a side mounted bailout breather for their recent long range exploration dives at Weeki Wachee Springs and other systems. The divers received their RBK training directly from Halcyon.

As KUR project director Andy Pitkin put it, “It is undeniably true that ‘simplicity is the ultimate sophistication,’ as Leonardo Da Vinci once noted. The RBK has proved itself to be close to a perfect tool for our particular application, far exceeding my initial reserved expectations.“

From its conception, it was quickly obvious that the RB80 would be around for a very long time. The simplicity, safety, and the robust mechanical nature of the unit, combined with rigorous training, and highly experienced users, arguably make RB80 and RBK the ultimate exploration tools.

Dive Deeper:

InDepth’s Rebreather Holiday Shopping Guide (2020)

Halcyon: Using The RB80 As A Sidemounted Bailout Rebreather by Andy Pitkin, Karst Underwater Research (2018)

GUE: DOUX DE COLY: GUE Expedition with RB80 (2004)

Introducing the RB80 by Michael Waldbrenner and Dr. Reinhard Buchaly

Deep Tech: Victory At Last (1998): Olivier Isler is setting penetration records with a triple-redundant semi-closed rebreather

David Rhea is an active GUE instructor and instructor evaluator, having been with GUE since the earliest days. An avid explorer with the WKPP since 1998, David has explored caves in China, Florida, Australia, Mexico, and France. A passion for diving started at age six, leading David to make his first dives at age nine. He became a scuba instructor at age 18. David has worked full time in the scuba industry for over 40 years, and has worked for Scubapro since 1995. David is as passionate today about exploration, teaching, and underwater photography and managing his Florida Scubapro territory as he has ever been.