Latest Features

Picturing History

Award winning photographer and tech instructor Becky Kagan Schott explains why these nine curated Great Lakes shipwreck photos are her favs.

Photos and words by Becky Kagan Schott

♪ ♫ Pre-dive Jam : Imagine Dragons – Whatever It Takes ♪ ♫

“All of these shipwrecks have compelling stories of tragedy and survival. Some are stories of mystery. Each one is very unique. What I’m trying to do with each is capture a bit of that story with a powerful image and match the two.”

SS Cedarville

Date Built: 1927

Date Sank: May 7,1965

Specific Location: Lake Huron, Straits of Mackanac

Depth: 34 m/110 ft

Discovered: Unknown

Did you know? Collision with the Norwegian ship MV Topdalsfjord caused her to sink when signals between the two ships were misunderstood. Nearby was the German freighter, M. V. Weissenburg. The captain of the German ship said when he saw the Cedarville disappear he stopped and lowered lifeboats to search for survivors and hung cargo nets over the side for anyone in the water to grab onto. Survivors who made it aboard the Weissenburg were given warm clothes and blankets, hot coffee, and tea. Some of the German sailors tried C.P.R. on the crewmen, and one crewmember who was suffering from low body temp was held under a hot shower and massaged to save his life. Of the 35-member crew, ten men died.

“Out of all the shipwrecks that I’ve shot in the Great Lakes, from shallow to over 300 feet deep, the Cedarville was one of the most challenging shipwrecks for me to photograph because of the lighting. It is very harsh with being in such shallow water and it being so big. And then with it being almost turtled, it’s very dark underneath, so it’s very shadowed. This image is special to me because it was about three years in the making. Every year I would go and experiment with new things, just trying to capture an image that really showcased the bow of the shipwreck—this massive freighter—where these fatal decisions took place in this wheelhouse. So, that’s why I have the wheelhouse illuminated, and I’ve got a diver up there sort of helping to illuminate the deck of the ship. Again, this one is special because it wasn’t just that I went and captured the image the first time around. It really took thinking and about it for three years to finally capture an image that I was happy with.”

Daniel J. Morrell

Date Built/launched: August 22, 1906

Date Sank: November 29, 1966, Caught in storm 70 mph, 7.6 m high waves,

Specific Location: Lake Huron, north of Pointe Aux Barques, Michigan

Depth: 67 m/220 ft – two sections, 5 miles apart.

Discovered:

Did you know? Coast Guard helicopter located a lone survivor, 26-year-old watchman Dennis Hale, near frozen and floating on a life raft wearing only a pair of boxer shorts, a lifejacket, and a pea coat, along with the bodies of three of his crewmates after a 40-hour ordeal in frigid temperatures.

“Seeing the Morrell really gives me chills. The bow section, the stern section, obviously the engine room here is in the stern. I wanted to capture an image that looked like somebody just went in and turned the lights back on. And since the shipwreck is covered in quagga mussels on the outside, there’s not a lot of features on the outside. But when you enter and you go inside, it is so clean. This image was another year in the making. And it was like a coordinated dance. I closed my eyes and I walked through every step of the dive so many times in my mind, from descending down the line and entering through the skylight. I had a safety diver that you can’t see pictured here because this is about 205 feet deep (62 meters) in 38°F/3.3ºC water, so it’s very cold. And I knew with three of us going in there, we would not have much time to execute the shot before it would get stirred up because it’s silty. But we got in, we did the light placements, and I probably only took six or seven shots. At that time, it wasn’t about quantity, it was more about quality. And I did end up capturing pretty close to the image that I wanted, one where you can see the diver looking at the telegraph. And then you’ve got the tool bench behind the diver where, if I were to take a close-up picture, there were still hammers and screwdrivers and everything. To me, this is where somebody worked, and this was the last place somebody worked before or while the ship went down. So it’s not about taking a picture of an engine room, but capturing that emotion and that human element.”

Cornelia B Windiate

Date Built: 1874 by Thomas Windiate at Manitowoc, Wisconsin

Date Sank: November 27, 1875

Specific Location: Presque Isle Michigan

Depth: 56 m/185 ft

Discovered: 1986 by divers in Lake Huron, near Alpena, Michigan, further east than expected.

Did you know? Cargo remains secure in her holds, and masts are still standing with rigging. It is unknown what sank her. Spray from huge waves may have coated it with layers of ice, adding a crushing weight to the overloaded ship. Handling the vessel likely became difficult and then impossible. The ship and crew vanished off Presque Isle.

“This image is a pretty special one to me. It was the first time I ever dived the Cornelia B Windiate. This wreck just captured my imagination. When I first saw it it was like being transported back in time, being on a piece of history. Like when I pictured a shipwreck as a kid, this is what I pictured as a shipwreck. And growing up in Florida, this isn’t what we’d see when we dived. So, dropping down on the Windiate the first thing I saw was the big wooden wheel on the back and then the freestanding masts and the lifeboat off to the side, which just captured my imagination. And this is a shipwreck with a lot of mystery still surrounding it. It disappeared in 1875 with a crew of nine, and the crew of nine was never found. And then the ship was actually thought to have sunk in Lake Michigan, but it was found in Lake Huron. So who knows what happened to the crew. But, since obviously the lifeboat is with the wreck, they didn’t make it. But it’s one of the most intact schooners that I’ve been able to dive with its intact cabin. There’s a spiral staircase leading down and two woodstock anchors on the front. And those standing masts are pretty special.”

The Sidewheel Steamer Detroit

Date Built: 1846

Date Sank: Collided with brig NUCLEUS in a heavy fog and sank, Bound Detroit to Chicago with 2 lumber scows in tow.

Specific Location: North of Point Aux Barques in 200′ of water. (Exact location unreported until she was located.)

Depth: 55 m/180 ft.

Discovered: Trotter in June of 1994

Did you know? Sits upright and the entire sidewheels are attached on both sides of the shipwreck with its walking beam engine in the middle.

“This was also a pretty unique wreck; diving it is like you’re going back in time because it sank in 1854. There are not a lot of intact wooden sidewheelers with intact paddle wheels on the side and with the walking beam engine. There used to be a bell, but unfortunately it was stolen. Here you see two very good friends of mine, Jim and Susan Winn, who passed away a couple of years ago on a different dive, which makes this photo even more special to me, even though it was special before that just because of the shipwreck itself. This is around 210 feet deep (64 m) so it’s a deeper wreck.”

Eber Ward

Date Built: Launched Spring of 1888; registered 7/21/1888 in Detroit, Michigan; 65 m/213 ft long, with a draft of 6.7 m/22 ft

Date Sank: April 20, 1909

Cause: Ran into thick pack ice; “running too fast.” Captain T. Lemay was found “guilty of misconduct, negligence, and inattention to duties” and had his master’s license revoked.

Specific Location: Straits of Mackinac, west of Mackinaw City, MI.

Depth: 36 m/110 ft. to 46 m/140 ft.

Discovered: In 1980 by “divers”.

Did you know? There were nine survivors of the 14 people aboard. Five people perished on the SS Eber Ward and were memorialized by the vessel’s wreck, which now forms part of the Straits of Mackinac Shipwreck Preserve.

“I just shot this one a couple months ago during this summer. And it was one of those days where it was dark and raining, and this wreck is in about 145 feet of water. So we knew it was going to be dark down there. Which can be disappointing in some ways, but in other ways, when I know something is going to be dark, I just know that lighting is everything. Lighting could really make this pop. So Kevin Bond helped me out by illuminating one of the anchors. And there’s like four different anchors on the bow of this wreck. It has this beautiful bow. It’s an interesting wreck. If he would’ve illuminated from the other side you would’ve seen this mushroom anchor that you can kind of see down on the far right-hand side. I like moody. And they don’t always have happy endings, so I think moody plays well with a lot of these wrecks.”

The Gunilda

Date Built: 1897 in Leith, Scotland, by Ramage and Ferguson; owned originally by F.W. Sykes from England, finally by Wm. L. Harkness. Cost $200,000 to build.

Date Sank: August 11, 1911, after running aground into McGarvey Shoal. Passengers taken off; Harkness stayed behind to supervise the salvage by tugboat, but after she was pulled free, she suddenly rolled over to starboard, filled with water, and sank. There were no casualties.

Specific Location: Northern Lake Superior, McGarvey Shoal, north side of Copper Island

Depth: 82 m/270 ft

Discovered: 1967, completely intact, but multiple salvage attempts failed.

Did you know? In 1980, Jacques Cousteau, with the research vessel Calypso and the diving saucer SP-350 Denise dove and filmed the wreck and called it “the best preserved, most beautiful and most prestigious shipwreck in the world”

“The Gunilda sits in 270 feet of water. I mean we’re not at 270 feet in this picture, probably more like 250 feet (77m). We just had such limited time. So my goal with the Gunilda was I wanted to create a photo that nobody had ever seen before. When I saw photos of this shipwreck before I’d been there, they were all close up shots and details of just the bell or details of the wheel or the binnacle. Small details. So I wanted to see if I could execute a shot that gave you a little bit more of a wide-angle look. It’s difficult because there is snow-like particulate in the water. So it was more difficult than I had imagined. And the visibility isn’t as good in Lake Superior. But I had two divers helping me out with this shot to help illuminate the flying bridge with the wheel and the binnacle and the telegraph and another one to help me illuminate the chart house. And then I also had some lights inside to help the windows glow, and put lights around the wreck as well. I think I’m the first to capture a wide-angle shot of the Gunilda. I’ve never seen another one like it.”

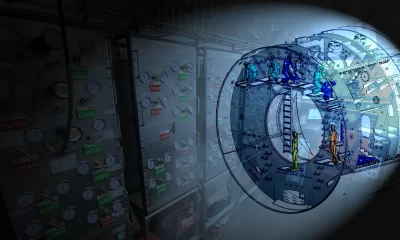

“This photo is special because it was extremely hard to execute, and it was a team effort. Everybody had to be on the same page, so this was a planned shot. It’s around 250 feet (77m) deep, and there’s absolutely no ambient light whatsoever. It is pitch black, and you are very far north in Lake Superior, so it’s just cold, dark, and deep. And you have very limited time at that depth. So the idea here was to have a couple friends illuminate through the skylight as if natural sunlight was pouring back into the wreck for the first time. And I had no on-camera lighting for this shot, so I just wanted it to appear as if the ship was floating again and the sunlight was pouring in through the stained glass window.

As you can see, the chairs and the table are bolted to the floor, and there is a fireplace in the background, and there is still a clock. Off on the far right-hand side, you can see the bend from my lens with the window there. The difficult thing with getting this shot is we couldn’t go inside these rooms. They are very small. So I had to gently stick my camera through a window. And you can actually see some of the glass shards at the bottom of the frame. When you’re in 37°F/3ºC water and you know that you’re going to have two hours of decompression to do, you don’t want to rip your dry suit. So you have to very carefully stick your hands or your camera through so you don’t cut or rip any part of your dry suit. My dive buddies did an amazing job helping me to achieve this image.

One of my favorite comments I ever got on this photo was, ‘I don’t know why everyone is making such a big deal over this photo.’ Since there is no diver in it, somebody thought it was actually on land and it was just a dusty old room with sunlight coming through. And then when it was explained that it was 250 feet (77m) underwater, and it was pitch black with no light, they were a little more impressed.”

FT Barney

Date Built: 1856 by William Cherry of Vermilion, Ohio. Owned by Lewis Wells, same location.

Date Sank: October 23, 1868. Carrying a load of coal, she collided with the schooner Tracey J. Bronson and sank in less than two minutes. No lives were lost. Both vessels were seen to be at fault.

Specific Location: Lake Huron, near Rogers City, Michigan

Depth: 49 m/160 ft

Discovered: 1987

Did you know? One of the most complete wrecks of a schooner of its era, with masts (with crowsnest) and deck equipment still in place

“This is another new shot that I just shot a couple months ago. The FT Barney was another very intact wooden schooner that I really wanted to get to. And this is also a very old schooner. And having an intact cabin and wheel and being just within technical range, around 150-160 feet (46-49m) deep was very appealing to me. But I just really liked the way the shot came out—kind of moody—with my buddy Bob illuminating the wheel and the cabin area. I just love these schooners. There’s something romantic about them. They bring you back in time.”

Typo

Date Built: 1873 in Milwaukee

Date Sank: October 14, 1899, after a collision with Ketchum, another schooner carrying coal for Racine, Wisconsin

Specific Location: Six miles east-southeast of Presque Isle light, Lake Huron

Depth: 56 m/185 ft

Discovered: Unknown

Did you know? Sits upright with bowsprit intact, two of the three masts still standing, and all rigging in place. Her bell has never been salvaged and remains in place, making her a ‘must do’ wreck. Four crew members went down with the ship, and divers are respectful to not disturb the remains. Ship type is a ‘canaler’ – built to fit the width and length of the Welland Canal.

“The Typo is another wooden schooner and the bowsprit is still intact with the rigging still on it. And you can see Jim illuminating that anchor with that forward mast with the crows nest still standing. The very first time I dived this and I took a photo of the bow of the wreck, just like this, I looked at the back of my camera and it didn’t even look real to me. I looked up at the wreck with my own eyes and just took it all in because it just looks surreal. It just doesn’t even look like such a wreck can exist. And it really does. What I love about this is just the standing masts, the bowsprit. It looks like it’s still sailing on the bottom.”

Dive Deeper

In addition to photography/cinematography, Schott is an accomplished author and has just begun creating 3D photogrammetric models. Here is some of her work:

Gunilda feature that aired in Canada

Video of wrecks in the straits

3D model: Sketchfab Cornelia B. windiate model

Alert Diver: Thunder Bay National Marine Sanctuary

Alert Diver: Straits of Mackinac Shipwreck Preserve

Michigan Blue et al: Dark Memories and Underwater Photographer Captures Forgotten Stories Beneath the Great Lakes and a video news series

Becky is a five-time Emmy award-winning underwater cameraman and photographer whose work appears on major networks including National Geographic, Discovery Channel and Red Bull. She specializes in capturing images in extreme underwater environments including caves, under ice, and deep shipwrecks. Her projects have taken her all over the world from the Arctic to the Antarctic and many exciting locations in between, filming new wreck discoveries to cave exploration and even diving cage-less with great white sharks. Her biggest passion is shooting haunting images of deep shipwrecks in the Great Lakes. Becky is a frequent contributor to numerous dive magazines, both US-based and international, and her photography has been used in books, museums, and advertising. She is also a technical diving instructor and leads expeditions all over the planet. www.LiquidProductions.com www.MegDiver.com