Community

Swing Through the Trees, Dive in the Seas: What Technical Diving Can Teach Arborists About Safety

Tree hugging arborist and safety consultant turned tekkie Brad Hughes is applying the lessons of technical diving to improving tree climbing safety. If the power saws don’t get you, the rapid descents will! Pre-climb checks anyone?

By Brad Hughes

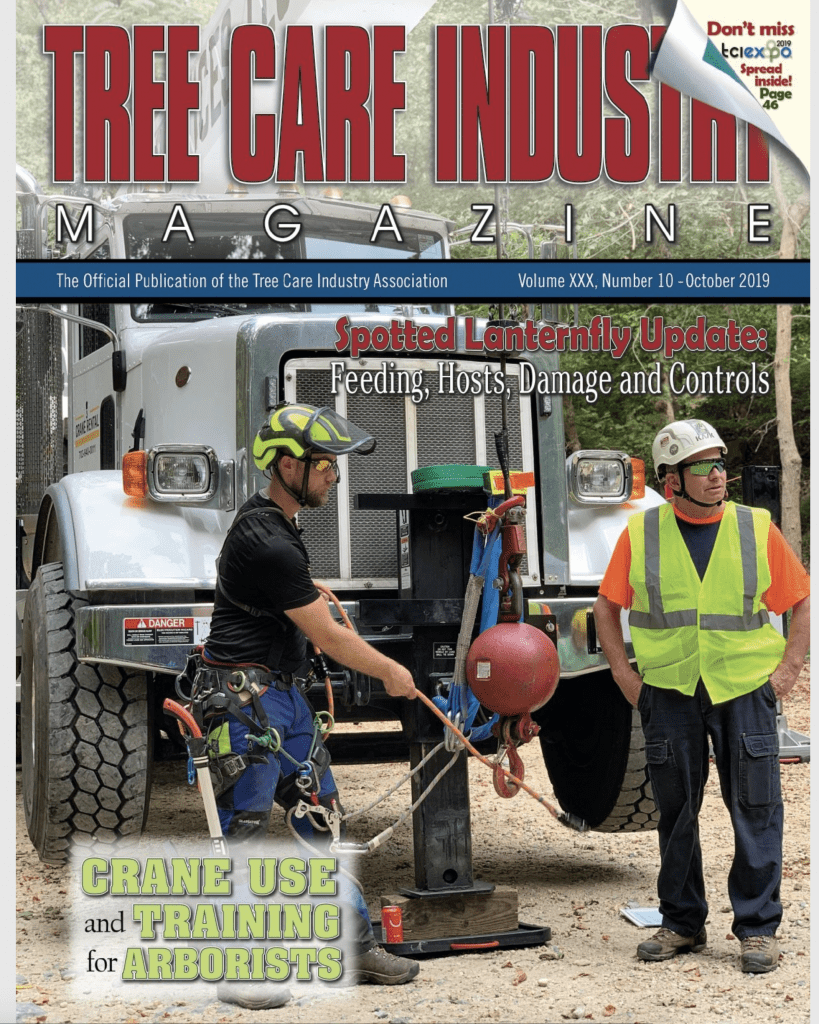

Header image courtesy of D. McLaughlin Photography

As many of you scanned the title of this article you were probably thinking, “What does diving have anything at all to do with tree climbing?” You may have added, “Whoever wrote this is a few split pieces shy of a full chord!”

Despite the naysayers, by the end of this discussion I hope to have convinced you all that, not only are there similarities between diving and tree climbing, but also there is something relevant to be learned from the way technical divers approach safety while operating in high risk environments. I also hope to encourage you to look outside the box to find new and novel ways to improve safety and performance for your organization and the tree care industry as a whole.

Photo by D. McLaughlin Photography.

When I started out in this industry, my job became my hobby, which I am sure is true for some of you as well. I would climb after work and on the weekends in an effort to move myself up the organizational chart from “Brush Dragger Extraordinaire” to “Guy Who Climbs Too Slow to Be Useful”. Eventually though, after reaching the lofty status of “Knows Enough to be Dangerous”, I started getting a little burnt out and determined I needed something other than work-related activities to occupy my free time. I decided to pursue technical diving, since I was already certified as an entry level diver. Through my experiences and interactions in diving I have been exposed to many diverse ideas that have added to my understanding of operating in high risk environments. I have come to realize there is much to be learned from seemingly unrelated industries and activities, each offering a different perspective and risk analysis.

Through my experiences and interactions in diving I have been exposed to many diverse ideas that have added to my understanding of operating in high risk environments.

Applying The Principals of Technical Diving

Technical diving is a leisure sport, not to be confused with commercial diving, which is a trade similar to rope access. For the purposes of this article, technical diving will refer to any diving in an overhead environment. Overhead environments include caves where there is a physical barrier to the surface and deep diving where an immediate ascent to the surface is not possible due to risk of injury caused by ascending too quickly. Though tree work and diving are vastly different, I began to see similarities between tree care operations and diving. Both divers and climbers operate in high risk environments, use unique technical skills to conduct their operations, and are not easily accessible by rescue personnel in the event of an emergency.

As I became more involved in diving and started reading training materials, talking with divers and instructors, and investigating accident reports, I realized many diving-related incidents shared common root causes with those that we commonly observe in tree work, including lapses in situational awareness, insufficient training, and a lack of planning and preparation. I began comparing technical dive training and procedures with those commonly employed in the tree care industry to see if I could glean any insights.

As a result, I have identified areas where safety and performance could be enhanced by implementing the mindset, practices, and procedures that I observed in the technical diving community. Though I cannot relay all of my insights in this article, I will focus on two areas where I see the most immediate benefit for the tree care industry. These specific topics were also chosen due to their familiarity; OSHA and ANSI standards already mandate job training, gear inspection, and job briefings. In many cases, though, these requirements are not being met. My intent is to illustrate how another industry takes a different and possibly more effective approach to a task that is familiar to us as tree care professionals, but I would be remiss if I did not mention the importance of culture.

In the absence of a willing culture, new ideas and perspectives will not flourish. The reason that some tasks—like job briefings and equipment checks—are often omitted can be attributed to a company’s or even an entire industry’s culture. Culture is an umbrella term that encompasses topics like leadership, accountability, attitude, just culture, and employee relations. In this context I am referring to an organization’s emphasis on safety and training. To put it simply, building a better checklist will do no good if it is not used. The technical diving community places an enormous amount of emphasis on safety and training which is reflected by its relatively low incident rate.

Dive Planning/Job Planning

Technical divers plan their activities with exacting precision. Once a dive has begun, it is impractical or sometimes impossible to retrieve a forgotten item, change equipment configurations, or get help in the case of an emergency; therefore, planning for each dive is critical. Technical divers will methodically plan their goals for a dive, assign team members areas of responsibility, calculate maximum amount of time allowed underwater at a given depth, evaluate decompression strategies, determine the amount and type of breathing gas to carry, identify environmental hazards, and complete gear inspections prior to entering the water. By applying this rigorous planning process to tree care operations, I believe that safety, performance, and profitability could be improved.

Photo by Brad Hughes.

Though we are not bound by the same constraints as divers, taking the time to identify hazards, assign tasks to the crew, create a detailed work plan, develop an equipment list, designate a drop zone and drag path, and plan contingencies will pay dividends overall. How much more efficient would your operations be if your employees were not required to go to the truck to retrieve forgotten equipment or maintain an item that should have been fixed after the last job. Have you ever arrived at a job site and realized that a necessary piece of equipment had been left at the shop? Have you ever climbed half way up a tree only to realize the main stem has a split in it?

Mistakes like these could be the difference between a job being profitable or not. I decided to try planning my jobs and briefing my crews like I would plan and brief a dive. The crews that I work with are extremely professional, but even so, occasionally items would be overlooked. After implementing an improved planning process, I noticed that small things that were occasionally missed before were now being identified and mitigated before we started. Items like small yard ornaments, sprinkler heads, pre existing property damage, forgotten PPE, and hangers in incidental trees along the drag path were being identified before the job started.

This might not seem like a meaningful improvement; however, if you consider the implications of a broken sprinkler head, a desecrated pet grave, allowing someone to work without PPE, or an injured employee, you can begin to see the value in a good plan. A mentor of mine once told me “Five minutes twelve times is an hour” in other words, little things add up costing lost time and money.

A mentor of mine once told me “Five minutes twelve times is an hour” in other words, little things add up costing lost time and money.

Training

As stated above, technical dive training is rigorous and demanding. Dive training is also progressive, structured, and roughly standardized across the sport. This is something that I believe the tree care industry needs to improve upon if we are to get the most out of our workforce. In the technical dive training curriculum that I am working through, a student starts in a class called Fundamentals and then if they pass would have the opportunity to move onto Cave 1 and so on. In between classes there is a requirement to make a certain number of dives in specific conditions to ensure the student is ready to move onto the next stage of training.

As a contract trainer, I have worked with companies to help them develop similar standardized training programs for their organizations. There are many benefits to having a structured training program in place. A structured training program provides documentation, which is important if a company were ever to have a serious incident. It is also repeatable. All trainees receive instruction on the same subject matter and are held to the same level of proficiency. This gives crew leaders and owners the ability to quickly evaluate where a particular employee falls on the skills spectrum and make crew assignments accordingly. Crew leaders would be able to immediately assess a crew member’s skill level and make job assignments that are appropriate even if that employee was not a regular member of their crew.

If we were able to standardize this across the industry, hiring decisions would be made simpler knowing that a prospective employee had attained a certain level of training, even if at a different organization. I am an advocate for assigning a time frame for an employee to remain in any one category of the training program, allowing them ample time to master the skills required, but also making sure that training remains a priority. There is always more to learn, and I think encouraging people to keep moving forward, and providing the structure to facilitate that, not only benefits them but the organization as well. In the end you will have a more experienced, safe, capable, and professional workforce at your disposal.

My hope is that by sharing my experiences with diving, I will encourage other members of the industry to share their experiences and observations regarding occupations and areas of interest outside of tree care. As a contract climber and trainer, it is my job to continually raise the bar for safety and performance for myself, my clients, and the industry as a whole. I hope that all of you reading this will also heed that calling and add your voice, so at the end of the day we may all walk away.

Dive Deeper

- A Day In The Life of a Arborist

- The Wild Trees: A Story of Passion and Daring – Richard Preston

- Arborist Swinging From a Palm Tree (This guy needs a tech diving class!)

Brad Hughes is the owner of Woodline Tree Care LLC. His company specializes in contract climbing and safety consulting within the tree care industry. Brad holds several credentials including being a Certified Arborist, Certified Tree Care Safety Professional, and an aerial rescue instructor approved by the Tree Care Industry Association. Brad has been involved in presenting and conducting demonstrations at industry events and, as well as conducting training for the National Park Service, OSHA and many others. When not swinging around in trees Brad spends much of his free time pursuing his other passion, diving. Brad was first certified by SDI in 2009 as an open water diver. Brad dove off and on as time allowed until he found GUE in 2017. After being introduced to some GUE divers his passion for diving really took off. Brad took Fundamentals in early 2018, and is currently preparing for Cave 1 in February of 2021.