Diving Safety

The Flexibility of Standard Operating Procedures

Instructor trainer Guy Shockey discusses the purpose, value, and yes, flexibility of standard operating procedures, or SOPs, in diving. Sound like an oxymoron? Shockey explains how SOPs can help offload some of our internal processing and situational awareness, so we can focus on the important part of the dive—having FUN!

By Guy Shockey

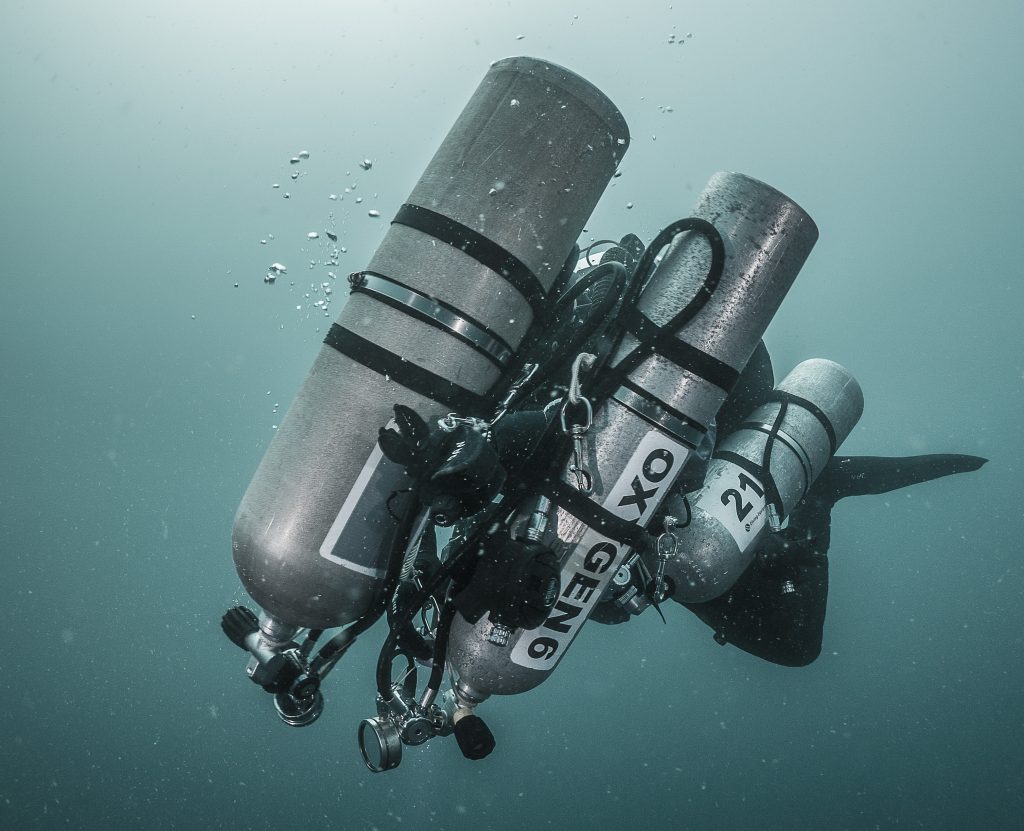

Header Image by Derk Remmers

At first glance, the title reads like a bit of an oxymoron. How can a standard operating procedure (SOP)—which implies a ‘one size fits all’ solution to problem solving—also be flexible? How can flexible also be firm?

One of the things that initially attracted me to Global Underwater Explorers (GUE) was the presence of SOPs. For anyone with a military background, SOPs were our bread and butter. You can create a good SOP while you have the time to think and plan. You can put them into practice, refine them over time, and keep them in place until new or better information comes along to change them.

For example, airline pilots have a binder full of SOPs for various contingencies. When something comes up, they turn to the correct page and find a list of actions to follow. Pilots understand that these SOPs represent the collective knowledge of many aviators and engineers that have come before them. Many of them have also been revised multiple times, codified, and then even revised after that. Some SOPs require commitment to memory because there may not be a lot of time, and pulling out a three-ring binder or flipping through your iPad to the correct page isn’t the appropriate action. In that case, then those same pilots practice these situations regularly in simulator training.

One of the primary values of an SOP is that it frees up a lot of situational awareness information processing. You are able to match up “mental models” to the current situation and, rather than processing your information in small bite-sized pieces, you are able to process “chunks” of information that match patterns of something that you know or are familiar with.

Let me create an analogy that may help make this clearer. If I were to give you a bowl of tomato sauce, some slices of pepperoni, some mushrooms, some cheese, and a piece of baked dough, you could eat them all one at a time and try to figure out what it was you were eating. Or, I can put all those ingredients on that same piece of dough, bake it, and you would instantly know that you were eating pizza. You don’t have to process all the ingredients one at a time. You already have an existing mental model that says “pizza.” We do this when we solve problems. We pattern-match and identify existing mental models all the time, and it’s actually the only way we can actually think as fast as we do. Many problems are actually solved with multiple mental models being applied together.

Having an SOP gives you the ability to solve problems more efficiently and effectively because you have a ready-made mental model or solution to a recognized problem. Think of every first aid course you have ever taken and the “ABCs” of first aid. SOPs are incredibly valuable in nearly every environment that includes potential risks.

If an SOP is shared, it also allows diverse groups to work together. It is no surprise that SOPs from various militaries of the world are often similar, even if they are written in different languages. From personal experience, NATO countries can coordinate and execute complex military operations because they share common SOPs that, if not identical, are very similar and don’t require much adjusting to mesh together. Common expectations and goals can be shared toward a common purpose.

When in time-sensitive environments, many of these SOPs and the corresponding mental models they help develop can be lifesaving. This doesn’t just apply to the military, but also to law enforcement, paramedics, firefighters, pilots, and any other profession that is often faced with time pressures in making critical decisions.

Do you share a common operational picture?

There is an interesting term often used in military circles called the “common operational picture” (COP). This is exactly what it sounds like, and is sometimes referred to as “a single source of truth.” Everyone involved in a decision-making cycle needs to be privy to the information that affects their decision. Sharing that information allows us to make informed decisions that often include SOPs. You could argue that we are creating a mental model that lets us apply another mental model!

Alright, so how exactly does all this apply to diving and GUE diving in particular? I’m pretty sure that many of you have already connected many of the dots.

In the GUE world, our divers create a COP at the beginning of the dive. We help reiterate this COP with our GUE EDGE pre-dive checklist, which is a great example of an SOP! We review the goals, team roles, our equipment, and the operational parameters of the dive, all in a standardized format that efficiently accommodates teammates from multiple different languages and cultures. I have performed GUE EDGEs in about 10 different languages and I only speak two! The fact that we were doing this in a standardized fashion meant I could follow along and knew what they were talking about.

As the dive plan complexity increases, so too does the COP become more complex. Some of our more ambitious exploration projects require even more time spent in planning than actual execution. But because there is a COP, coupled with SOPs (I know that’s a lot of acronyms), these projects usually go off without a hitch.

During the dive, there are multiple times that we have team-expected actions that are based on SOPs, and this contributes to and reinforces our COP. It is almost as if we are filling in a PDF form as we go along and confirming the various pieces of information that we need to complete the entire “form” or plan.

In the case of emergencies, we have ready-to-implement SOPs for just about any equipment malfunction from valve failures to losing your mask. We practice these SOPs so that, in real time, we can employ them in a timely fashion and resolve the problem. These SOPs are just like the ones I mentioned at the beginning of this article and were developed over time and refined with successive reviews and after-action analyses. Finally, they have been codified, and you can now find them in our GUE SOP manual! You will also notice that this manual is of a particular “version,” which tells you that the SOP is constantly being fine-tuned in a dynamic process.

How Can An SOP Be Flexible?

In reality, it isn’t the actual SOP that is flexible, but it is the degree of flexibility it provides to the dive plan itself that is of value. Let me give you an example from the technical diving world.

Imagine the team is diving on a wreck and experiences a delay on the bottom for whatever reason. It could be that it was done on purpose (discovery of pirate gold!) or maybe it was imposed upon the team as a result of any number of problems, like dealing with an equipment problem or an entanglement, for example. The dive is longer, the decompression obligation is now going to be longer, and there are some decisions to be made.

Having an SOP here can help provide a solution to the problem with no mess and no fuss. The divers dig into the bag of tricks they learned in GUE technical training, and because of their common operational picture and team-expected actions, they apply the SOP they practice regularly and modify their decompression schedule to suit the new bottom time. What could have been an exciting moment for many divers turns into just another discussion point for their debrief after the dive!

So, while SOPs are usually not flexible in and of themselves, they allow for a great deal of flexibility while diving by freeing up mental processing power and providing ready-made and practiced solutions to potential problems.

GUE SOPs presuppose the presence of personal diving skills at a high level, and assume that factors such as good buoyancy and trim are second nature. In fact, many of the SOPs state the first step in resolving a problem as “stabilize” or “stop” in all three dimensions. GUE divers see that, as the diving gets more complex, the SOPs also get more complex. For a new GUE Fundamentals diver, demonstrating some of the SOPs required to pass muster as a Tech 2 or CCR 2 diver look more akin to channeling “the force” than anything else. However, like most things, perfect practice produces perfect performance, and so it’s just a matter of putting in the repetitions.

For me, diving has never been the end but the means to the end. Anything I can do to make those means take up less mental and physical horsepower means that I can devote more of the same to the end goal. And at the end of the day, I am really all about that pirate gold!

Dive Deeper:

Note that GUE members or divers taking a GUE course receive access to GUE’s 30-page manual, Standard Operating Procedures.

Guy Shockey is a GUE instructor and trainer who is actively involved in mentoring the next generation of GUE divers. He started diving in 1982 in a cold mountain lake in Alberta, Canada. Since then, he has logged somewhere close to 8,000 dives in most of the oceans of the world. He is a passionate technical diver with a particular interest in deeper ocean wreck diving. He is a former military officer and professional hunter with both bachelor’s and master’s degrees in political science. He is also an entrepreneur with several successful startup companies to his credit.