Equipment

They Helped Foment a Dive Computing Revolution: RIP Cochran Undersea Technology (1986-2020)

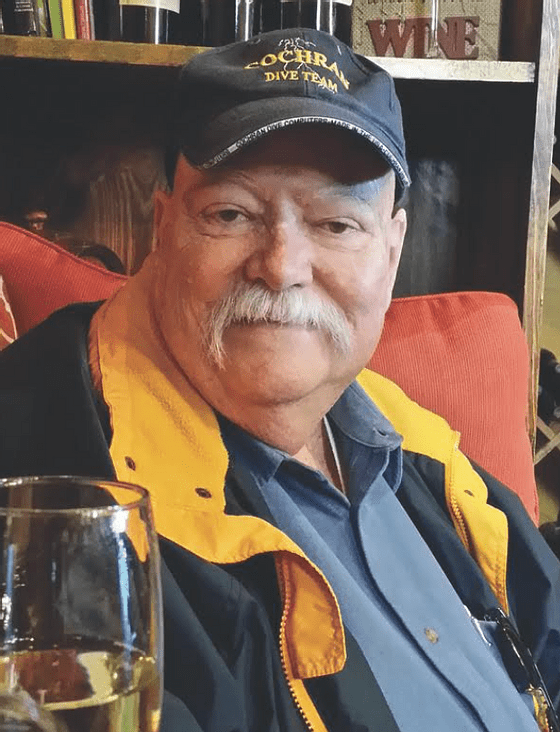

Latin American distributor for Cochran Undersea Technology and certifiable dive geek Carlos Lander recounts the many firsts and innovations in dive computing created by microprocessor pioneer Mike J. Cochran (1941-2018). These included the first wireless air-integrated dive computer, automated sensors, hands free gas switching, tap interface, compartment-level conservation factors, what-if software, and the “Cochran Navy”—used to by the US Navy, to run their proprietary VVAL 18 algorithm.

By Carlos E. Lander

Header image courtesy of C. Lander

Carlos Lander was the distributor for Latin America for Cochran Undersea Technology.

Michael James Cochran, genius and founder of Cochran Undersea Technology, revolutionized the design of dive computers (DCs) with the company’s state of the art US Navy Computer that impacted the entire DC industry. But before exploring the accomplishments of Cochran Undersea Technology, let’s answer an integral question: “Who was Michael James Cochran?”

Mike was born in Daytona Beach, Florida, on May 21, 1941. He worked on a missile tracking ship as a young adult but also had an illustrious career in electronics, receiving 57 patents, including ones for the microprocessor and microcomputer chip.1 The microcomputer chip patent was assigned to Texas Instruments (TI)—where Mike worked for many years—and issued to Gary Boon and Michael J. Cochran in July 1971.

For his work on that microcomputer chip, Mike won an IR-100 Award from Industrial Research Magazine (now known as R&D World Magazine). After he left TI, he worked with NASA and invented a DC for their astronaut training program. He founded Cochran Undersea Technology in 1986, and began designing and manufacturing DCs for recreational, sport, commercial, and military diving applications.

In 2016, he was awarded the honorary position of Admiral in the Texas Navy, an accolade commending exceptional community service. In that same year, he won the New Orleans Grand Isle (NOGI) Award—frequently known as the Academy Award of Diving—which recognizes pioneers of the underwater world.

Sadly, Mike passed away on December 2, 2018, at the age of 77, leaving behind a lasting legacy of studies and research in electronics. Mike was always driven by passion—so much so that he worked until the end of his life, having never created a plan for Cochran Undersea Technology to continue without him.

The Cochran Undersea Technology employed brilliant and gifted people such as Martin Heerschap, designer and engineer for the Cochran closed circuit rebreather (CCR) and liaison to the US Navy throughout the Navy DC’s development. Sales manager and tech instructor Larry Elsevier was another who worked closely with Cochran clients including the US Navy and NATO. He passed away in 2014. There was also Jeff Loudan, physicist, mathematician, and software engineer; Stuart McNair, engineer; and John Corso, talented diver and the face of the company before Mike’s passing.

Creating An Advanced Dive Computer

Everything started in 1991 when Cochran Consulting Inc—the parent company to Cochran Undersea Technology—filed a patent for an “advanced dive computer,” which was intended to become an Oceanic air integrated DC.2 While that specific product was never patented, Cochran’s DC led to a huge advancement in the field. First, Mike made a DC from a Single Board Computer (SBC), and then he programmed everything in an “assembly language,” securing very high-speed, real-time calculations on a reliable DC.

An SBC refers to any computer that contains all of its components in one circuit board. This configuration is perfect for devices with limited hardware space, such as a DC. SBCs are self-contained and energy-efficient, important elements under diving conditions.

An assembly language is an architecture-specific, low-level programming language, and Mike used one to efficiently compile a very complex algorithm including a set of variables that, at the time, did not exist in a DC (breathing parameters being one).

The final product included a microprocessor, a depth and pressure transducer, an electrically conductive metal clasp, and other components that worked efficiently in a small package within a very low power consumption unit.

Consequently, Mike decided to produce his own line of DCs, dubbed Nemesis in the United States, and Aquanaut in the EU. Although the company worked with different brands, in the end they decided to concentrate on their own, the Cochran Dive Computer. No other manufacturer at the time designed and built every component of their DC in-house.

Cochran was the first company to produce a hoseless DC with the following design features:

- Mike’s design allows the main computer to be attached to the tank, so all the information gathered by the pressure transducer is transmitted to a diver’s wrist monitor (a second computer) in real time3, including the diver’s breathing parameters and workload. The wrist unit could be used independently as a DC in the event of a tank unit failure. Other brands used a transmitter attached to the tank, limiting the amount of information that could be sent to the main unit in short data bursts.

- As determined by Cochran, the cases on both units were air-filled (at 1 atm), ensuring that the cases were manufactured with material that was capable of withstanding extreme depths. Taking this approach required fewer case penetrations—such as buttons—and ensured an effective, long-term seal. In addition, the battery compartment was sealed from the electronics and built with materials that wouldn’t corrode. In an extremely rare case of flooding, the only damage would be to the battery compartment and not the electronics.

- The case was equipped with three electrically conductive metal clasps instead of pushbuttons. Those stainless contacts, in conjunction with the electronics, could detect the difference between saltwater and freshwater and thus refine the depth calculation. They could also distinguish metallic objects and fingers via electroconductivity.

- Another cool patented feature was the implementation of a vibration detector inside the unit which allowed the user to perform quick functions, like tapping the unit for five seconds to turn it on, or tapping it once to turn on the back light.

- The Cochran computer accurately measured and recorded the altitude (pressure) every minute whether it was on or off, accounting for minute changes of nitrogen levels in tissue.4

- Other contemporary DCs accounted for changes in decompression conservatism, and while some commercially available computers offered conservatism customizations, they didn’t provide adjustment calculation guidance. The majority of DCs based the conservatism factor in changing altitude; instead, Cochran used gas-loading to add conservatism in proportional increments so that divers both understood and controlled their conservatism.

- Cochran’s DC’s tandem PC software featured two capabilities not offered by any other manufacturer at the time. First, the PC software ran the same algorithm as the DC, behaving exactly as the DC did on a dive. Divers could perform a trial run on the PC graphically or review an existing profile. Secondly, divers could transfer gas loading and altitude characteristics from one DC unit into another DC unit. For example, if one computer malfunctioned, information would transfer from one unit to another. Therefore, divers could continue to dive with the new computer without noticing any difference.

- Perhaps most importantly, the Cochran DC never locked a diver out; most DCs would block access for 24 hours if the diver violated a stop. Cochran’s DC allowed them to continue their dive, and the DC would continue off-gassing at their current depth.

The Proprietary Cochran algorithm

Mike exchanged ideas with dive experts while developing Cochran’s proprietary algorithm, including Dr. Bill Stone, Dr. RW Bill Hamilton, and Capt. Edward Thalmann of the US Navy. He designed the circuit board with the algorithm in mind. During this period, Capt. Thalmann was developing the Navy’s proprietary VVAL18 algorithm with the intention of using it in a forthcoming Navy DC. His plan was to be able to test the DC on the manned test-dive data to evaluate its performance against the algorithm.

Once Cochran Undersea Technology was awarded the contract to build the Navy DC, they had access to all the scientific studies, probabilistic software, and anecdotal data on the installation of VVAL18 into a DC, which was pivotal to the development of Cochran’s own decompression algorithm. Cochran’s algorithm for the Nemesis included compensation for a bubble formation, and the Gemini—based on the Nemesis prototype—added variables for ascent rate and breathing parameters. The algorithm is based on a modification of Haldane’s decompression model, with compartments between five and 480 minutes.

There were several versions of the Cochran algorithm: 14, 16, and 20 compartment models. In the case of the 20 compartment version, the algorithm included fast compartments to compensate for helium gas and added a compensation for microbubbles related to ascent rate velocity. The model also used the same linear off-gassing from the Thalmann algorithm but included more than the fast compartment and ascent velocity to compensate for the aforementioned microbubble formations.

DC algorithm evaluation has been the subject of some research. For example, Dr. Carl Edmonds compared DC responses to a series of bounce dives. Dr. Karl E. Huggins used the same technique to evaluate DC algorithms by testing them on profiles that had known human subject results.

In his article published in 2004, Huggins notes that DC manufacturers did not validate their algorithms with human subject tests, so running a DC against a battery of previously tested dive profiles provided some rudimentary level of validation. So, when it came to validating their algorithm for use in both the Nemesis and Navy DCs, Cochran had the advantage of accessing the Navy’s database of man-tested dives.

Along with validation against the Navy’s database, the Cochran DC was validated against NOAA’s custom tables on the wreck of the USS Monitor, and the tables and DC were said to have matched well throughout the project.

In a 1989 Undersea and Hyperbaric Medical Society (UHMS) Workshop on Validation of Decompression Tables, UHMS determined that decompression algorithm validity could only be proven using primary data, such as results derived from controlled laboratory conditions. However, secondary data such as anecdotal performance reports could be cited as an operational evaluation but wouldn’t be considered proof of validity.

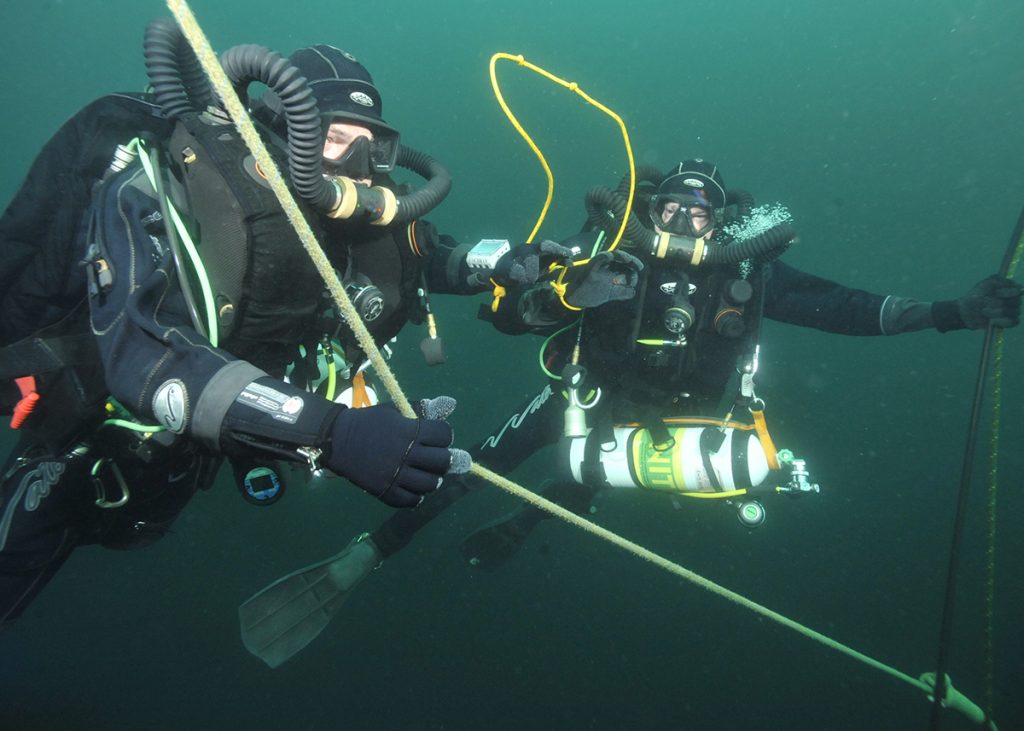

Cochran’s Navy DC and what made it so special

In 1996, there were no commercial DCs running the VVAL18 decompression algorithm. The US Navy Experimental Diving Unit (NEDU) sought a manufacturer to install the VVAL18 on a DC following their specifications, which were far from simple.

Cochran won the bid (being the only DC designer and manufacturer entirely in-house likely had much to do with it) and delivered five modified Commander DCs with the VVAL18 algorithm, which they called “Cochran Navy.” After a few modifications, Cochran developed additions to the Single Board Computer (SBC) that allowed for massive dive profiling memory and a one-second sample diving profile (the Navy required a maximum of two seconds). The finished product was a DC that handled large amounts of data and self-test diagnostics.

Due to the breathing parameters, the DC would operate with air if the depths were shallower than 23 m/75 ft, or at PPO2 = 0.7 (MK16 MOD 0 UBA) at further depths. Additionally, hands-free Gas Switching was implemented to eliminate the need for buttons5. Part of the computational power was required for this, as the switch function would depend on depth and time. Also, the DC was programmable on the surface or via PC.

The device computed decompression properly whether the diver was below or above the stipulated stop. The residual gas was based on the diver’s depth: a real-time-calculator, without gimmicks. Therefore, the DC never shut down or left the diver hanging. Other advances were handling of the magnetic signature, EMF emissions, and visible light emissions (red light) required for Explosive Ordnance Disposal (EOD) work, and for stealth. The DC could be programmed for the needs of the mission with the Navy’s Analyst computer software.

According to probabilistic decompression models for the profiles tested on the Cochran Navy DC, the average risk predicted of decompression sickness occurrence was low: less than 1%, as expected. Therefore, the DCs were validated by faithful replication of the decompression schedules when exposed to simulated manned tested-dives.

In Conclusion

The computers made by Cochran Undersea Technology, while advanced for their time, were misunderstood and misused by many. Still, I consider Cochran’s Gemini DC the best ever made. If you’re not breathing from the back-gas and can reach certain pre-programmed depths, the computer automatically knows that you’re breathing from the deco bottle. If you start breathing from the back-gas again, automatically switching back without needing to push any buttons is an astounding characteristic unmatched by any other DC.

Unfortunately, the absence of a marketing division in the company gave Cochran the reputation of producing a military-only DC. The EMC-20H, a later DC, was also very advanced for its time, so it was sad to see Cochran vanish. I am comforted by the fact that I still have a few Cochran DCs I can use, and that they will serve me for many years to come.

I want to thank Martin and John for our conversations, and for their help in getting the facts straight.

Footnotes:

- Patent No. 4074351

- Patent Nos. US4949072, 4999606

- Transmitting information every second reduces noise; the power transmitter and a 250 kilohertz frequency results in a strong communication between units and protection from interference with other devices such as camera strobes and scooter motors.

- When a diver changes from a lower altitude to a higher one, the computer detects this change and adds nitrogen to the tissue compartments. The differential pressure between the nitrogen in the body and the higher altitude must be equalized (outgassed). Conversely, when a diver changes from a higher altitude to a lower one, the computer detects this change and removes nitrogen from the tissue. The computer automatically reacts to long-term stays at a constant altitude. If a dive is made while at altitude (whether the computer has already automatically reacted or not), the nitrogen algorithm within the Dive Computer is adjusted depending on the exact depth.

- Patent No. 5794616

Dive Deeper

Cochran Undersea Technology Technical Papers:

Technical Publications (Various issues re: Cochran dive computers)

Batteries Caveat Emptor, April 2013

Batteries: Disposable vs Rechargeable, April 2013

Environmental Concerns, May 2013

Cochran Dive Computer Firsts, September, 2017

Carlos Lander—I’m a father, a husband, and a diver. I’m a self-taught amateur archaeologist, programmer, and statistician. I think that the amateur has a different mind set than the professional and that this mindset can provide an advantage in the field. I studied economics at university. My website is Dive Immersion. You can sign up for my newsletter here.