Diving Safety

What Happened to Solid State Oxygen Sensors?

The news in 2016 that Poseidon Diving Systems would be incorporating a solid state oxygen sensor in their rebreathers sent a buzz through the rebreather community. Galvanic sensors, along with their legacy-1960s “voting logic” algorithms to boost reliability, had long been considered the weakest link in closed circuit rebreathers. Many heralded Poseidon’s subsequent 2017 roll-out as the dawn of a new era in rebreather safety. Five years later, Poseidon remains one of two companies (the other strictly military) to have adopted optical sensors. Technology reporter and tech diver Ashley Stewart examines some of the reasons why.

by Ashley Stewart.

Header image: Karst Underwater Research (KUR) rebreather divers at Weeki Wachee. Photo by Kirill Egorov

For years, it’s been said there’s a revolution coming for the closed-circuit rebreather— a new, more reliable, safer replacement for the traditional electro-galvanic oxygen sensor, widely considered the weakest component of rebreathers. In March 2017, that revolution looked to be just over the horizon. Poseidon Diving Systems began shipping an offboard solid state sensor to supplement the MKVI’s and SE7EN’s galvanic sensors and offered to license the technology to other manufacturers. Though Poseidon subsequently incorporated the solid state sensor into its SE7EN rebreathers, nearly five years have passed, and not much else has changed.

Poseidon remains the only manufacturer using solid state sensors in recreational rebreathers. No other companies have licensed Poseidon’s technology. Major tech diving manufacturers—including JJ-CCR and Divesoft—say they don’t believe the technology in general is ready for use in rebreathers. Some manufacturers worry that the sensors won’t function accurately in humid environments over a wide range of pressures, and they claim that addressing these challenges will be costly. Meanwhile, divers who tested Poseidon’s sensors offered mixed reviews, and even the inventor who sold the sensor validation technology patent to Poseidon believes they should be used along with traditional sensors. (Poseidon gives divers the option of combining the sensors).

Oxygen sensors are the enabling technology that made mixed gas rebreathers possible, replacing rebreathers that could only be used with pure oxygen. In 1968, marine scientist Walter Starck introduced the first commercial CCR, called the Electrolung, which used polarographic sensors. The next year, BioMarine Industries launched its CCR-1000, the predecessor of the US Navy’s Mk-15/16. The unit was the first mixed gas rebreather to use galvanic sensors, which do not require a power supply.

In addition to removing a diver’s exhaled carbon dioxide, a rebreather must measure and maintain a safe and efficient level of oxygen, as measured by the partial pressure of oxygen, or PO2, via oxygen sensors.

Measuring PO2 correctly is critical, and failures can be fatal. Too little oxygen can cause hypoxia and loss of consciousness, and too much can result in central nervous system toxicity and convulsions. Since sport divers began using CCRs over twenty years ago, both conditions have caused numerous drowning fatalities.

With the exception of Poseidon and military manufacturer Avon Underwater Systems, modern close circuit rebreathers have more or less used the same type of sensor since the 1960s. Rebreathers typically use three galvanic sensors, averaging the readings of the two closest sensors and ignoring the third in a protocol called “voting logic,” originally created by Starck in response to the sensors’ noted unreliability.

Even with this voting logic, however, the sensors can be unreliable (See “PO2 Sensor Redundancy” in Dive Deeper below). The galvanic sensors are cheap and time-tested, but they need to be recalibrated before every dive and expire after about a year. The new sensors—called “solid state sensors” or optical sensors—are expected to be more precise, reliable, and durable, though significantly more costly.

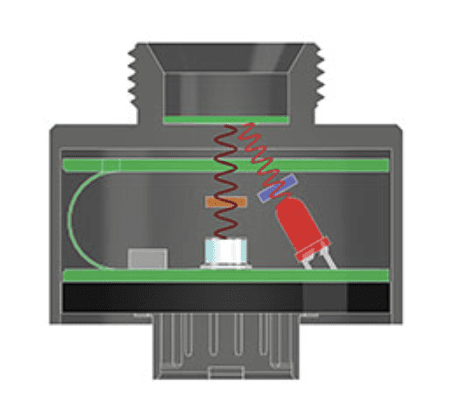

Galvanic sensors are essentially wet-cell batteries that generate a millivolt current proportional to the PO2 in the loop. Conversely, Poseidon’s solid state sensor uses luminescent quenching, wherein a red LED light excites the underside of a special polymer surface, which is covered with a hydrophobic membrane and exposed to the gas in the breathing loop. A digital color meter then measures the responding change in fluorescence, which is dependent on oxygen pressure, and an algorithm calculates the PO2.

Experts more or less agree that the right solid state sensor could make rebreathers safer, but the market is split on whether the technology is ready for use in rebreathers and just how much better they’d have to be to justify the cost.

Field Test Results

Poseidon advertises its sensor as “factory-calibrated and absolute, delivering unsurpassed operating life, shelf life, and calibration stability.” Richard Pyle, a senior curator of ichthyology at Hawaii’s Bishop Museum who works with Poseidon-affiliated Stone Aerospace, has tested Poseidon’s sensors for years, initially as a passive offboard check against Poseidon’s traditional galvanic sensors. Later, in November 2019, he said he began testing Poseidon’s prototype with the solid state sensor as the primary sensor in the unit. “From my perspective as a rebreather diver, this is the most significant game-changing way to know what you are breathing,” Pyle said. “We will never go back to the old oxygen sensors.”

Pyle said he’s yet to fully analyze the data he’s collected to compare the performance of the solid state sensors against the galvanic sensors, but that he’s had zero failures with the solid state sensors in the time he would have expected to have 50 to 100 failures with the galvanic sensors.

Likewise, Brian Greene, a Bishop Museum researcher who has tested the Poseidon sensors with Pyle, estimated that he’s made hundreds of dives with the solid state sensors without failure. But, not everyone has had this experience.

Sonia Rowley, an assistant researcher at the Department of Earth Sciences in University of Hawai’i at Mānoa, told InDepth that she experienced a variety of repeated failures when testing Poseidon’s system alongside Pyle beginning in 2016 and 2017, and Rowley dictated to InDepth specific dive logs detailing many of the failures. She wrote about her experience in the book “Close Calls.”

Poseidon CEO Jonas Brandt said the company has tested the sensors since 2017 at different depths and temperatures, and that it has only seen one possible failure.

Arne Sieber is a sensor technology researcher who said he developed the O2 sensor validation technology used in the Poseidon rebreather and sold the patent to Poseidon. Sieber is now researching uses for the solid state sensor including in the medical market. He told InDepth he believes the best way to incorporate the solid state sensors into rebreathers would not be to substitute one for the other, but to combine sensor types and design a rebreather that incorporates both.

Traditional galvanic sensors have advantages over the solid state sensors, Sieber said—they’re cheap, simply designed, low-voltage, and time-tested. Also, while solid state sensors are very accurate at measuring low PO2, they become less sensitive at about 1.6 bar, and are more prone to incorrect readings of higher PO2 levels than galvanic sensors. As for whether the sensors can function in humid environments, Sieber said the sensors can work well in liquids, such as when used for blood analysis (though the sensors are used to measure much lower partial pressures of oxygen) and for measuring oxygen content in the sea. Liquid can delay the amount of time it takes a sensor to read a partial pressure, but it does not falsify the results, Sieber said. Of Poseidon’s system, Sieber said, “It’s a good start. It’s very important that someone starts. Someone always has to be the first one.”

Brandt said divers have the option of combining sensors in the company’s SE7EN rebreather, using either two galvanic sensors, two solid state sensors, or one of each, and said it could be argued that using one of each sensor is the most reliable.

Meanwhile, a catalyst may be coming to encourage the development and adoption of solid state sensors in Europe, Sieber said. European Union rules restrict the use of hazardous substances in electrical and electronic equipment, but galvanic sensors (which have an anode made of lead) have been granted an exemption in medical products because there is not a suitable alternative. The exemption is set to expire.

Poseidon’s solid state sensor sells to end users for as much as around $1,500USD, and its SE7EN rebreather units use a maximum of two onboard sensors. [Note: Poseidon sells the sensor for 6800SEK plus VAT from its website, which equates to 944 USD, some outlets in the states sell them for much higher]. Galvanic sensors, meanwhile, cost around $100USD, last one year and divers use three at a time. And, that’s just the cost of the sensors themselves: Manufacturers have to make significant investments in, and upgrades to, electronics systems to accommodate solid state sensors.

As for how long the sensors actually last, even the manufacturers don’t yet know. Poseidon has some from 2014, and they still work but have to be factory calibrated every two years. Galvanic sensors need to be replaced annually, while solid state sensors are expected to last much longer.

Brandt chalks the debate about its sensors up to competitiveness in the market. “I don’t think anyone likes that somebody cracked the nut,” Brandt told InDepth. Poseidon is ready to share the technology with other dive companies and manufacturers, Brandt said, but there have been no deals to date. “We wanted to raise the bar in technology and safety with the rebreathers, and to be honest, we haven’t said to anyone in this business that this technology is exclusive or proprietary.”

Market Interest

When the company first debuted its sensor, Brandt reported that companies like Hollis and Shearwater Research expressed interest in licensing the technology, but nothing has come so far of those discussions. Brandt did say one manufacturer reached out right before the pandemic. He declined to say which, but shared that it was a European company. Hollis brand manager Nick Hollis said his team recalls a conversation with Poseidon, but that it was back in 2014 or even earlier.

Shearwater director of sales and marketing Gabriel Pineda said the company is still interested in solid state sensors, but they see an issue with the price. “If you make the economic case of traditional galvanic sensors versus solid state or optical sensors, you have to dive a lot, and it takes a long time for these to make economic sense for a diver.”

Of course, Shearwater is not a CCR manufacturer, but the company is interested in seeing whether the sensors would be viable for use with its electronic control system that is used by a majority of rebreathers on the market. Shearwater currently has no immediate plans to license the technology from any manufacturer but Pineda said the interest remains.

Meanwhile, Poseidon’s solid state sensor CCR is still making headway, Brandt said. The current biggest buyer of the Poseidon units is the military (Brandt said three European Union countries’ forces are actively using the sensors). The sales have continued throughout the pandemic, and, over the past six months, Poseidon has started an upgrading program, allowing divers to add the new sensors to their old units. Poseidon is looking into a program Brandt compares to Apple Care, where customers can pay a fee for maintenance throughout the life of the sensor.

Meanwhile, Avon Underwater Systems is using three solid state sensors in its MCM100 military rebreather. Kevin Gurr, a rebreather designer and engineer who sold his company, VR Technology Ltd., to Avon, said the company uses the sensors “because of the increased safety and the decreased user burden as far as daily calibration.”

Gurr, who designed and produced the Ouroboris and Sentinel closed circuit rebreathers at his prior company VR Technologies Ltd., believes it’s the cost that has discouraged other manufacturers. “It shouldn’t be about cost at the end of the day,” Gurr said. “The digital interface is so much safer.”

Martin Parker, managing director of rebreather manufacturer AP Diving, said his company follows solid state sensor development but has yet to come across a sensor that meets its accuracy requirements. One such sensor using luminescence quenching can achieve good accuracy through a replacement disk the user must apply to the sensor surface after each use.

“Having been in the diving business for 50 years, we don’t believe it is on any diver’s wish list to have to re-apply every diving day a new component, as simple as that is to do,” Parker told InDepth. “With no easy external measure of accuracy prior to the dive, it is easy to foresee that many divers would ‘push their luck’ and use the discs for multiple days, then when they get away with it, they would encourage other divers to do the same… with the inherent risk of DCS or O2 toxicity.”

Parker said that he’s aware of two additional sensors under development, but neither has shown a working product yet. He declined to identify any of the manufacturers, citing commercial sensitivity. “Hopefully, we will get these to evaluate in the next 12 months,” Parker said.

Divesoft co-founder Aleš Procháska said he believes Poseidon’s approach to the sensor could “lead to success.” Speaking generally about solid state sensors rather than about Poseidon’s specifically, Procháska said his company isn’t yet utilizing solid state sensors because he believes the sensors are unable to function in humid environments with extreme water condensation and not applicable over a wide range of pressures. To be able to use one of these sensors in a rebreather, Divesoft wants it to be durable in high humidity, consume less energy, and have a good price-to-lifetime ratio.

“It is possible to build a CCR with the currently available O2 solid state sensor but not without sacrificing important properties of the breathing apparatus,” he said, such as size and energy. “Overall, the reasons why no one currently sells this technology on the market seems to be quite simple. It’s extremely difficult to come up with a suitable and functional principle that would lead to a cheap, small, and low energy consuming solid-state sensor. Despite this, I do believe that it’s only a matter of time until someone solves this one.” Asked via email about the status of DiveSoft’s own work on the technology, Procháska replied, “Well, as I said earlier, it’s just a matter of time,” adding the text, “Aleš smiles.”

Halcyon COO Mark Messersmith said that divers are slow to embrace new technologies in general, and the current sensors just aren’t deficient enough to merit widespread adoption or the investment from manufacturers. “It’s not unlike many other technologies,” Messersmith told InDepth. “People are often slow to embrace a new technology if the existing technology is functional. The existing tech needs to be vastly deficient, and existing oxygen sensors are still largely functional.”

The bottom line: Solid state sensors might very well be safer, but there isn’t enough incentive for the market to make them a reality.

David Thompson, designer of the JJ-CCR, told InDepth they don’t use the sensors because he doesn’t believe the technology is ready yet and research in that area is extremely expensive and difficult for what he believes is essentially a small market. “Analog cells have a long history, and in the right hands are very reliable, easily available, and have a long history of working in a rebreather environment which is very hostile,” Thompson said, adding that high humidity and temperature in a rebreather is a challenge for any sensor. “I am sure it will be in the future, but that future won’t be here yet.”

Dive Deeper:

InDepth: Where Have All the Sensors Gone? Assessing the Global Oxygen Sensor Shortage

Rebreather Forum 3 Proceedings: PO2 Sensor Redundancy by Nigel A. Jones p. 193-202

Alert Diver: Oxygen Sensing in Rebreather Diving by Michael Menduno

Wikipedia: Electro-galvanic oxygen sensor

Ashley Stewart is a Seattle-based technology journalist and GUE Tech 1 diver. Reach her via email: [email protected], Twitter: @ashannstew, or send a secure message via Signal: +1-425-344-8242.